Products

-

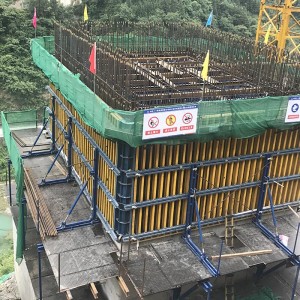

H20 Timber Beam Column Formwork

The timber beam column formwork is mainly used for casting columns, and its structure and connecting way are quite similar to that of wall formwork.

-

Wing Nut

The Flanged Wing Nut is available in different diameters. With a larger pedestal, it allows a direct load bearing on walings.

It can be screwed on or loosened using a hexagon wrench, thread bar or hammer. -

Single Side Bracket

Single-side bracket is a formwork system for concrete casting of single-side wall, characterized by its universal components, easy construction and simple and quick operation. Since there is no wall-through tie rod, the wall body after casting is completely water-proof. It has been widely applied to the outer wall of basement, sewage treatment plant, subway and road& bridge side slope protection.

-

Tie Rod

Formwork tie rod performs as the most important member in tie rod system, fastening formwork panels. Usually used together with wing nut, waler plate, water stop, etc. Also it is enbeded in concrete used as lost part.

-

H20 Timber Beam

Lianggong H20 Timber Beam is made from carefully selected high-quality solid fir wood. H20 Beam features a plastic protectivedevice to reduce the risk of scratching the exterior of thebeam. With a double T-shaped cross-section, these H20wooden beams are suitable for various formwork andsupport applications.

At present, we have a large-scale timber beam workshop and a high-class production line with daily output of over 2000m. -

Aluminum Column Formwork

Aluminum Column Formwork has emerged as a game-changing benchmark in contemporary construction, tailored to meet the rigorous demands of large-scale projects with its peerless operational efficiency, robust longevity, and pinpoint structural accuracy.

The cornerstone of its superiority lies in its premium high-strength aluminum alloy composition. This advanced material strikes an optimal balance between featherlight maneuverability and formidable load-bearing capacity, streamlining on-site handling procedures and slashing installation timelines dramatically. What’s more, its innate anti-corrosion properties effectively ward off rust and wear, extending the formwork’s service cycle far beyond traditional alternatives.

Beyond material excellence, this formwork system delivers unwavering structural stability. It maintains its original shape without warping or deforming even after countless cycles of use, consistently yielding concrete walls with exact dimensional specifications and flawlessly smooth surface finishes. For a wide spectrum of wall construction tasks, it stands as the definitive solution that merges reliability with top-tier performance.

-

Steel Wall Formwork

Steel formwork is a critical component in construction projects, playing a vital role in ensuring quality, enhancing efficiency, and reducing costs. It is categorized into four main types: flat formwork, beam formwork, column formwork, and special-shaped formwork.

-

Steel Column Formwork

Steel column formwork is a specialized standardized steel system, custom-engineered for pouring and forming concrete cylindrical, square, and special-shaped columns. As core equipment for column structure construction, it offers broad applicability, meeting the needs of diverse projects including building, bridge, and tunnel auxiliary works.

-

Single-Side Bracket

Single-side bracket is a support system designed for one-sided concrete wall casting, featuring universal components, simplified installation, and rapid construction. The absence of through-wall tie rods ensures fully waterproof concrete walls. This system is widely used in basement exterior walls, sewage treatment plants, subway structures, and slope protection for roads and bridges.

Our single-side bracket system has been developed in response to on-site needs, specifically to address formwork reinforcement challenges. With a rational and efficient design, it offers construction convenience, ease of operation, faster assembly, optimized load distribution, and improved labor productivity. The system supports a maximum single-pour height of 7.5 meters and consists of three main components: the single-side bracket, the formwork panel, and the anchoring system.

-

Cantilever Climbing Formwork

The cantilever climbing formwork, CB-180 and CB-240, are mainly used for large-area concrete pouring, such as for dams, piers, anchors, retaining walls, tunnels and basements. The lateral pressure of concrete is borne by anchors and wall-through tie rods, so that no other reinforcement is needed for the formwork. It is featured by its simple and quick operation, wide range adjustment for one-off casting height, smooth concrete surface, and economy and durability.

-

Ring-Lock Scaffolding System

The Ringlock scaffolding system is a modular, heavy-duty solution designed for safety, speed, and strength. Its unique ring-and-stud connection ensures a rigid, reliable structure with quick, tool-free assembly.

Built from high-grade steel, it supports significant loads and adapts to complex structures with ease. The system prioritizes safety with positive-locking connections and full compliance with international standards.

Ideal for demanding construction and industrial projects, Ringlock offers unmatched stability, efficiency, and long-term value-a trusted choice for professionals worldwide.

-

Box Culvert Formwork

Box culvert formwork is a versatile construction solution developed for culvert structures, drainage systems, and small-scale bridge projects. Designed for efficiency and durability, it supports a wide range of structural requirements across different infrastructure applications.