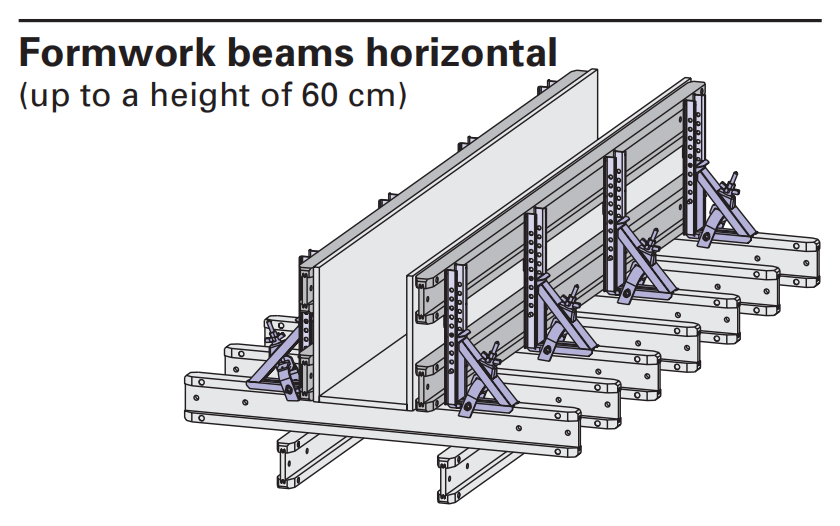

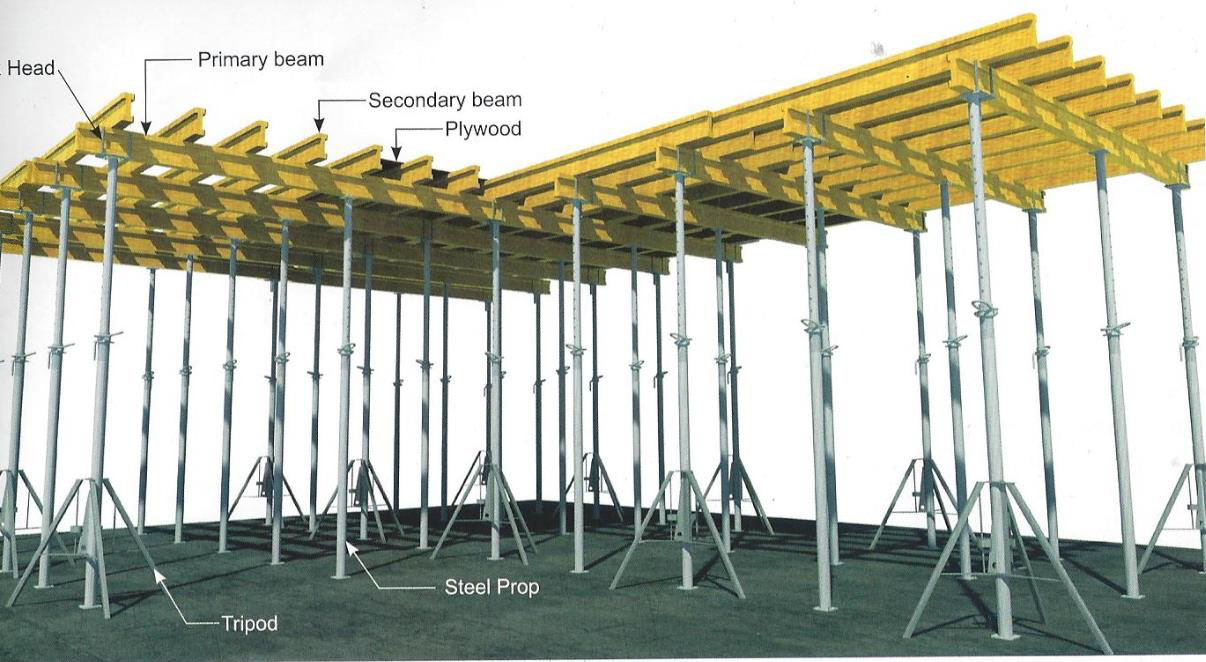

Easy Assembly & Dismantling –It is lightweight and can be installed more quickly, ,reducing workers' fatigue.

High Flexibility – The layout can be adjusted freely to suit irregular room sizes, varying slab heights, and areas with dense beams.

Durable & Reusable – Moisture- and wear-resistant treatment ensures the beams and panels withstand multiple construction cycles.

Cost-Saving – It is more cost -effective than metal formwork systems. lt can be reused 15 to 20 times and does not require heavy machinery.