Original Factory Wet Spraying Machine - Hydraulic Tunnel Linning Trolley – Lianggong

Original Factory Wet Spraying Machine - Hydraulic Tunnel Linning Trolley – Lianggong Detail:

Product Details

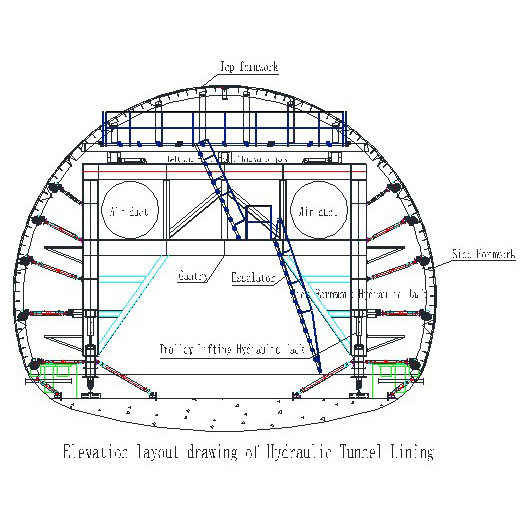

Designed and developed by our own company, hydraulic tunnel lining trolley is an ideal system for formwork lining of railway and highway tunnels. Driven by electrical motors, it is able to move and walk by itself, with hydraulic cylinder and screw jack being used to position and retrieve the formwork. The trolley has many advantages in operation, such as low cost, reliable structure, convenient operation, fast lining speed and good tunnel surface.

The trolley is generally designed as a steel arch type, using a standard combined steel template, without automatic walking, using external power to drag, and the detachment template is all manually operated, which is labor-intensive. This type of lining trolley is generally used for short tunnel construction, especially for tunnel concrete lining construction with complex plane and space geometry, frequent process conversion, and strict process requirements. Its advantages are more obvious. The second tunnel reinforced concrete lining adopts a simple arch frame design, which solves these problems well, and at the same time, the engineering cost is low. Most of the simple trolleys use artificial concrete pouring, and the simple lining trolley is filled with concrete conveying pump trucks, so the rigidity of the trolley should be particularly strengthened. Some simple lining trolleys also use integral Steel Formwork, but they still use threaded rods and do not move automatically. This type of trolley is generally filled with concrete delivery pump trucks. Simple lining trolleys generally use combined steel formwork. Combined steel formwork is generally made of thin plates.

The rigidity of the steel formwork should be considered in the design process, so the spacing between steel arches should not be too large. If the length of the steel formwork is 1.5m, the average spacing between the steel arches should not be greater than 0.75m, and the longitudinal joint of the steel formwork should be set between the push and the push to facilitate the installation of formwork fasteners and formwork hooks. If the pump is used for infusion, the infusion speed should not be too fast, otherwise it will cause deformation of the composite steel formwork, especially when the lining thickness is greater than 500mm, the infusion speed should be slowed down. Be careful when capping and pouring. Pay attention to the pouring of concrete at all times to prevent the concrete pouring after filling, otherwise it will cause mold explosion or deformation of the trolley.

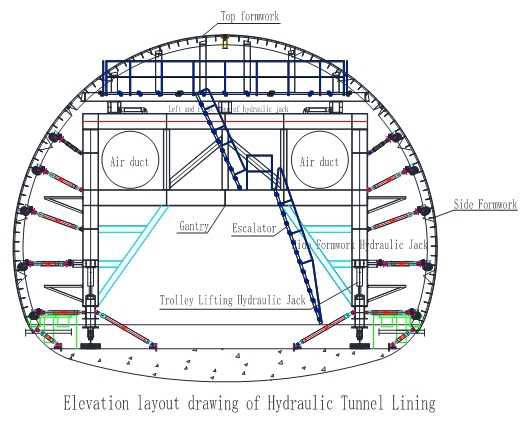

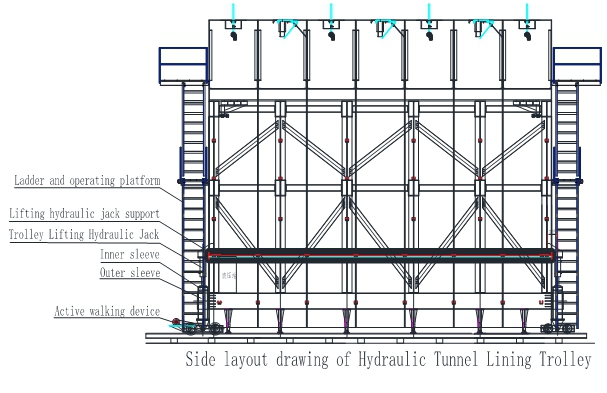

Structure diagram of hydraulic tunnel lining trolley

Technical parameters

01. Specifications: 6-12.5 m

02.Maximum lining length: L=12m (can be adjusted according to the customers)per unit

03.Maximum passing capacity: (height * width) construction does not affect the car at the same time

04.Crawling ability: 4%

05. Walking speed: 8m/min

06.Total power: 22.5KW Traveling motor 7.5KW*2=15KW oil pump motor 7.5KW

07.Pressure of hydraulic system:Pmqx=16Mpa

08.Unilateral modulus removal of formwork:Amin=150

09.Left and right adjustment of horizontal cylinder:Bmax=100mm

10.Lifting cylinder: 300mm

11.Maximum stroke of the cylinder: lateral cylinder 300mm

12. Horizontal cylinder: 250mm

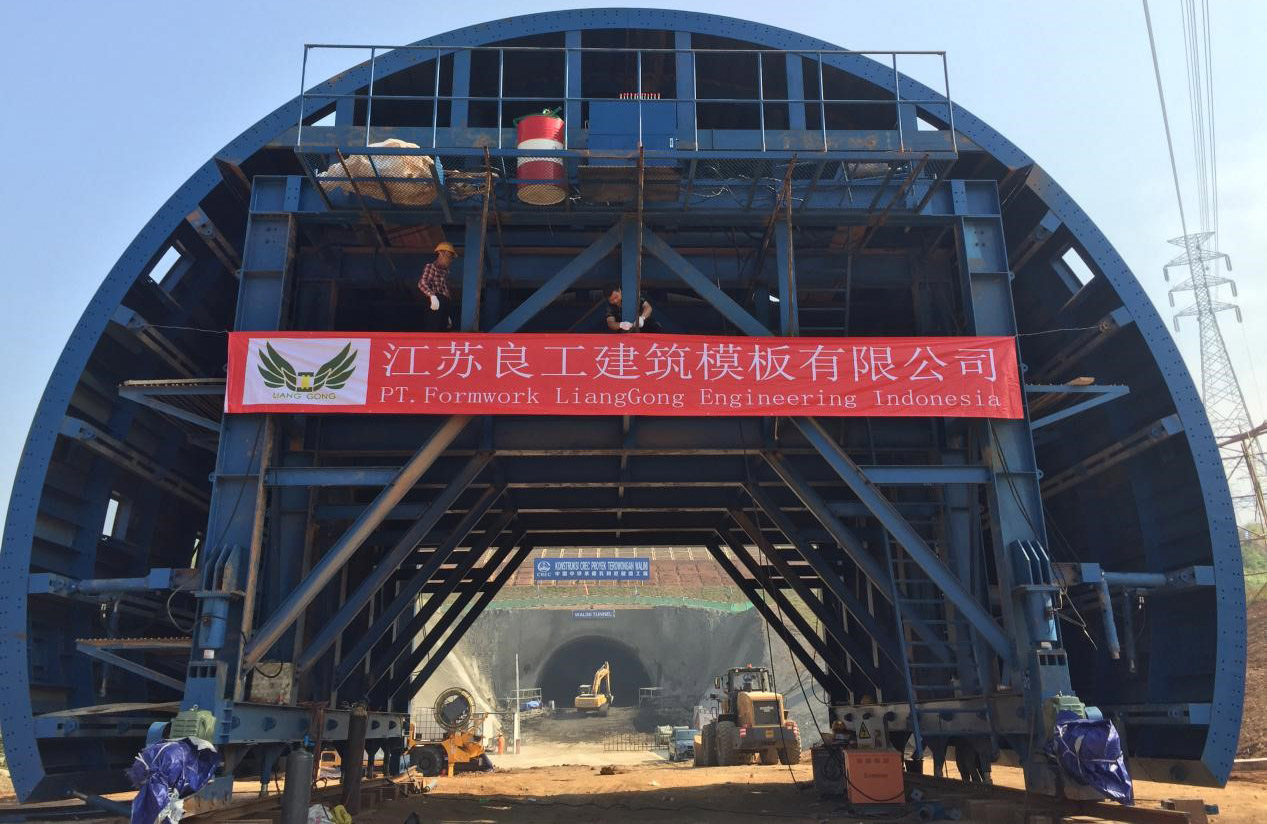

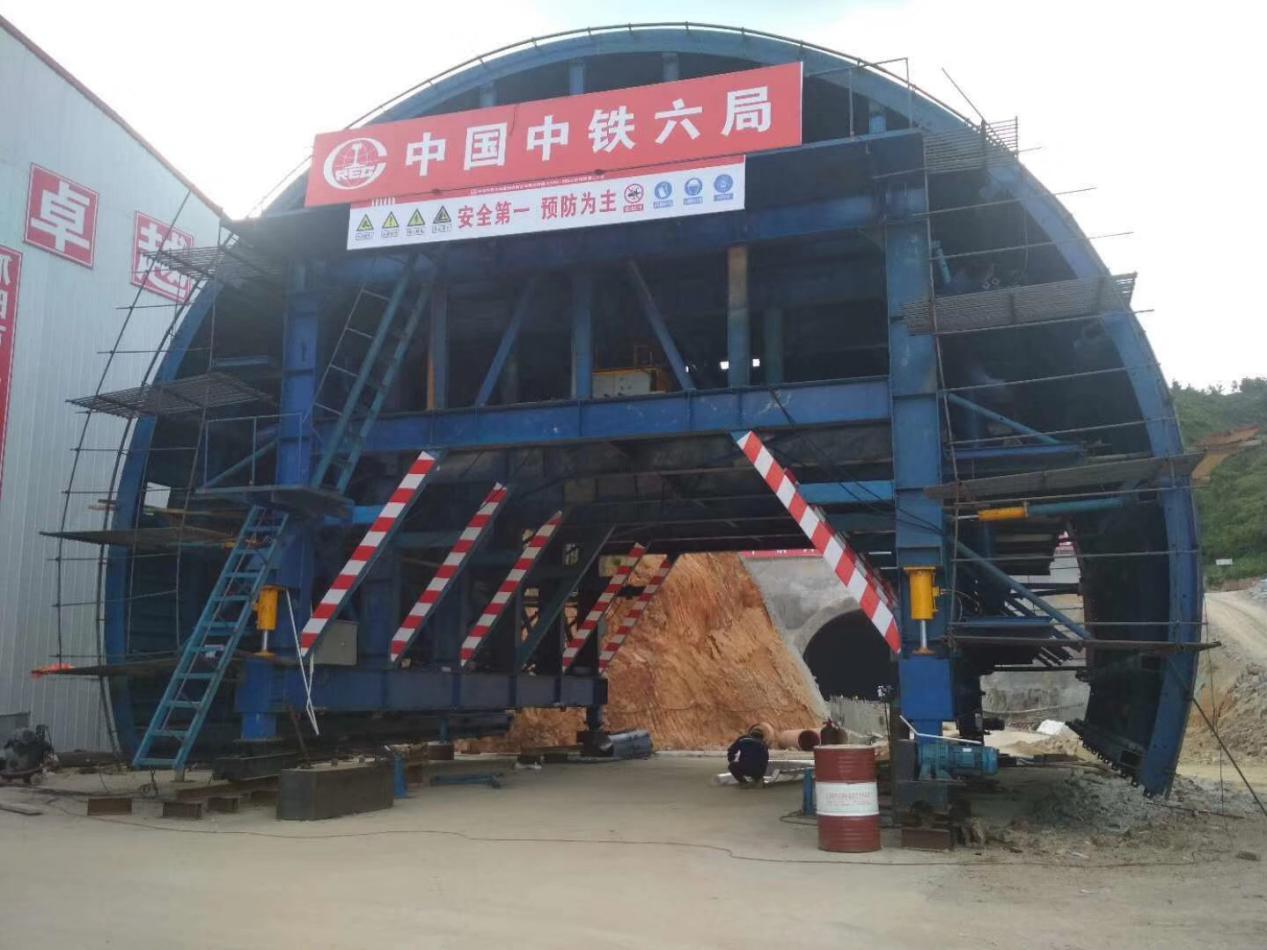

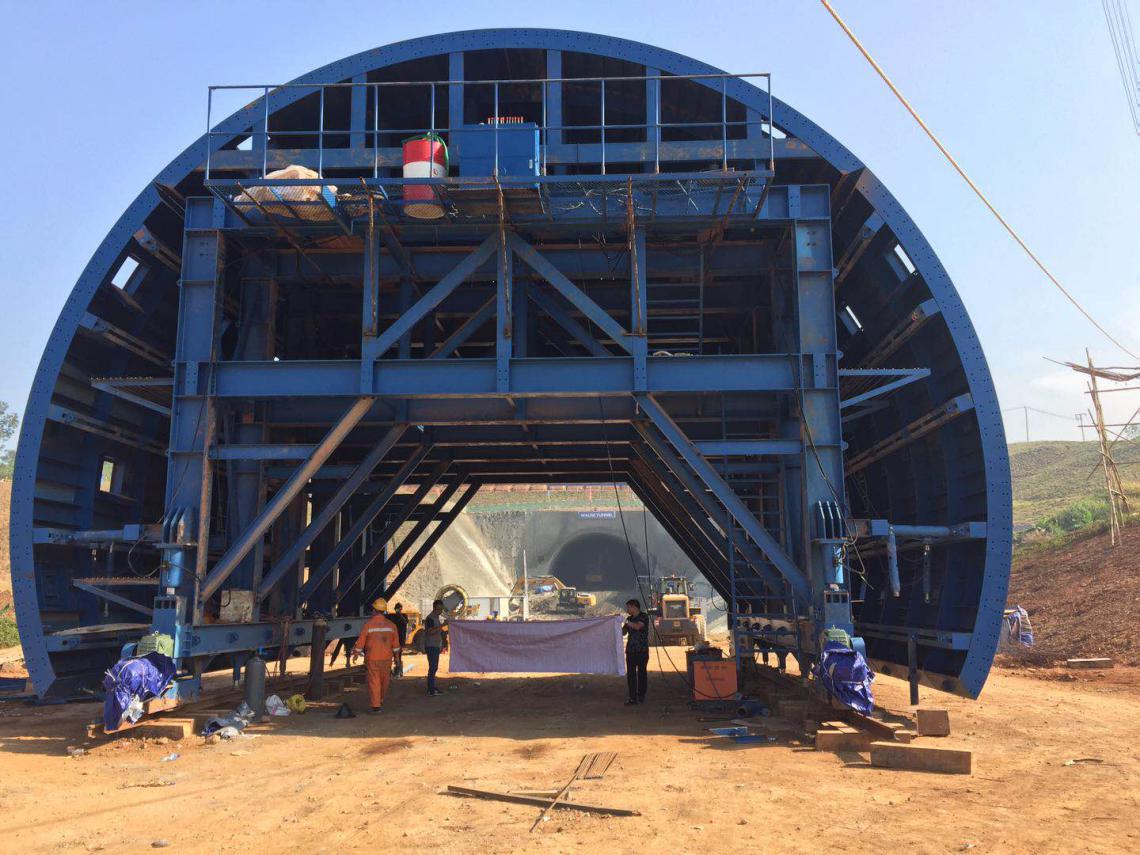

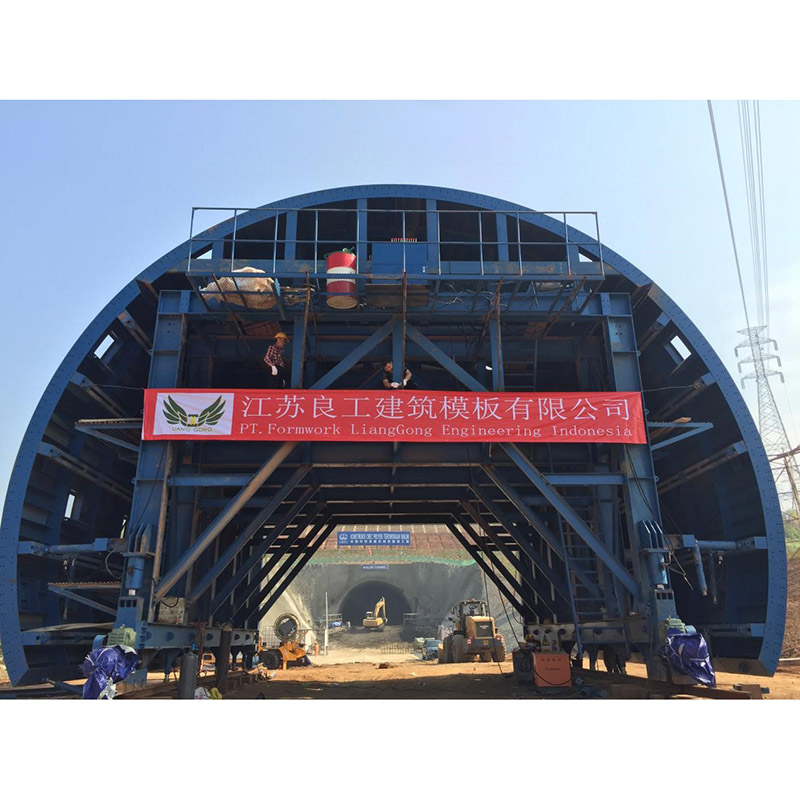

Project application

Product detail pictures:

Related Product Guide:

With this motto in mind, we have turn out to be amongst probably the most technologically innovative, cost-efficient, and price-competitive manufacturers for Original Factory Wet Spraying Machine - Hydraulic Tunnel Linning Trolley – Lianggong , The product will supply to all over the world, such as: Sevilla, Turkey, Iraq, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we'll continue to develop, to deliver the high-quality items and services, and promote lasting cooperation with our customers, common development and create a better future.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.