Online Exporter Cantilever Climbing Formwork - Hydraulic Auto Climbing Formwork – Lianggong

Online Exporter Cantilever Climbing Formwork - Hydraulic Auto Climbing Formwork – Lianggong Detail:

Product Details

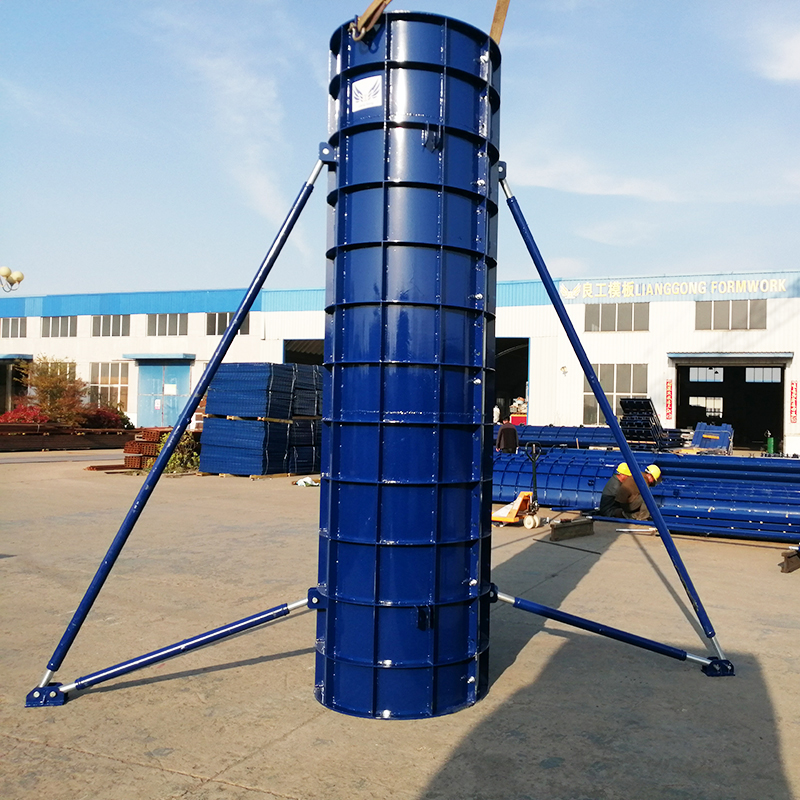

The hydraulic auto-climbing formwork system (ACS) is a wall-attached self-climbing formwork system, which is powered by its own hydraulic lifting system. The formwork system (ACS) includes a hydraulic cylinder, an upper and lower commutator, which can switch the lifting power on the main bracket or climbing rail. With the power by the hydraulic system, the main bracket and climbing rail are able to climb respectively. Therefore, the complete hydraulic auto-climbing system (ACS) climbs steadily without crane. No other lifting device is needed when using the hydraulic auto-climbing formwork, which has the advantages of being easy to operate, fast and safe in the climbing process. ACS is the first-choice formwork system for high-rise tower and bridge construction.

Characteristics

1.Hydraulic auto-climbing formwork can climb as a complete set or individually. The climbing process is steady, synchronous and safe.

2.The brackets of the auto-climbing formwork system will not be dismantled until the construction period finished, thus saving space for the site and avoiding damage to the formwork, especially to the panel.

3.It provides all-round operating platforms. The contractors do not need to set up other operating platforms, thus saving the cost on material and labor, and improving safety

4.The error of structure construction is small. As work on correction is simple, the construction error can be eliminated floor by floor.

5.The climbing speed of the formwork system is fast. It can speed up the whole construction work (average 5 days for one floor).

6.The formwork can climb by itself and cleaning work can be done in situ, so that the use of tower crane will be greatly reduced.

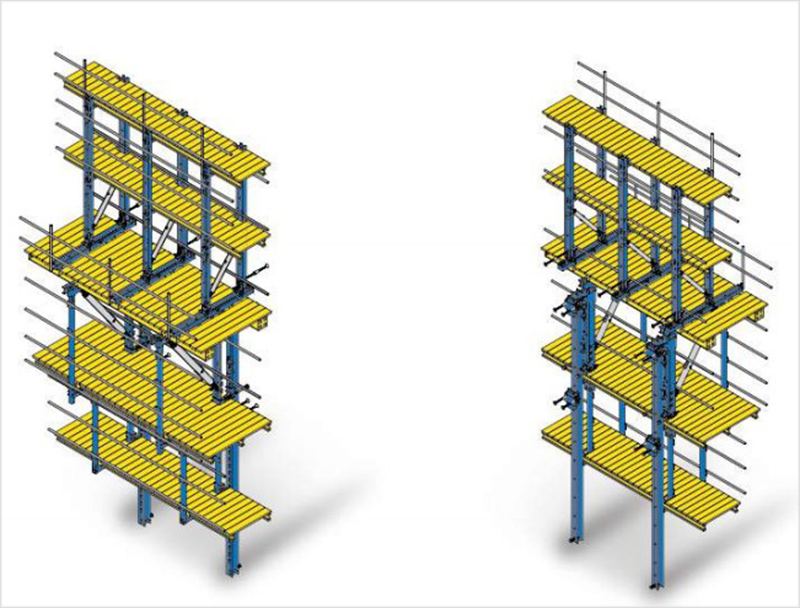

Two types of hydraulic auto-climbing formworks: HCB-100&HCB-120

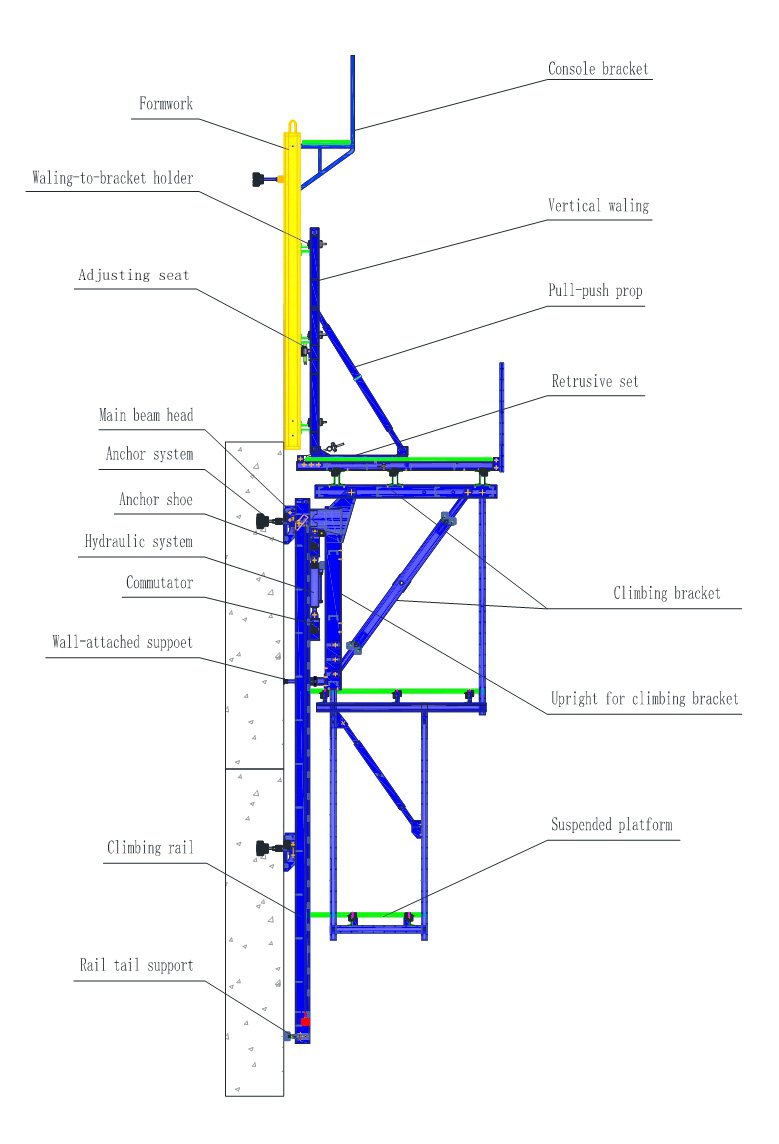

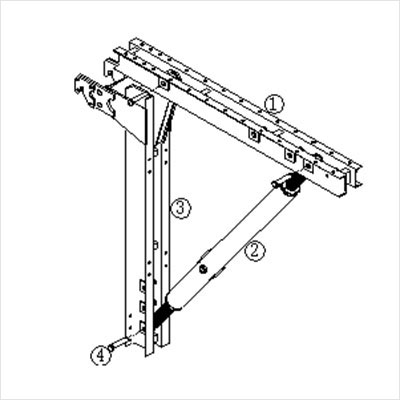

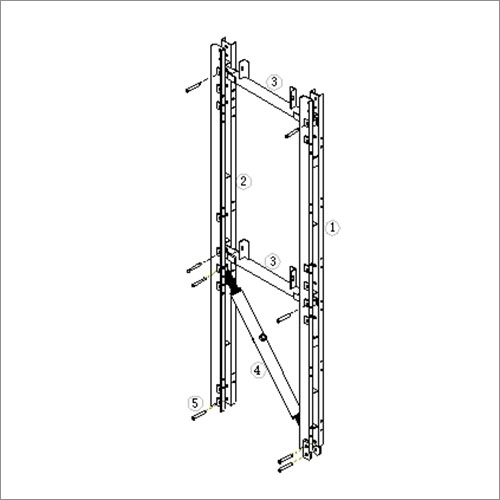

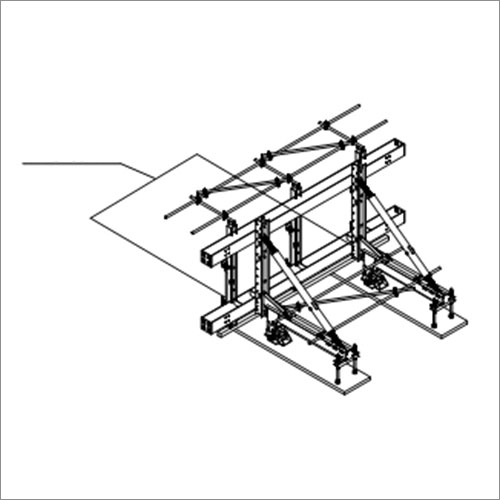

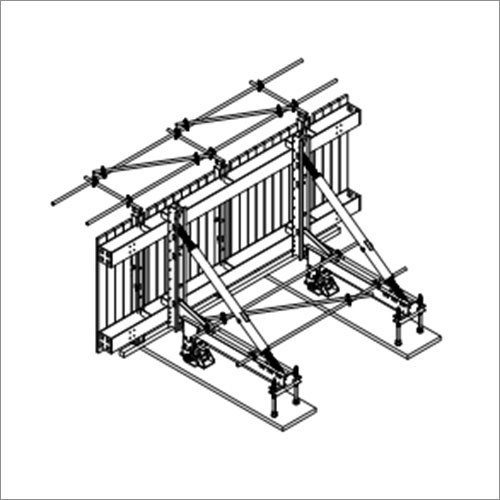

1.Structure diagram of diagonal brace type

Main function indicators

1.Construction load:

Top platform ≤0.75KN/m²

Other platform: 1KN/m²

2.Electronically controlled hydraulic

lifting system

Cylinder stroke: 300mm;

Hydraulic pump station flow: n ×2L /min, n is the number of seats;

Stretching speed: about 300mm/min;

Rated thrust: 100KN & 120KN;

Double cylinder synchronization error: ≤20mm

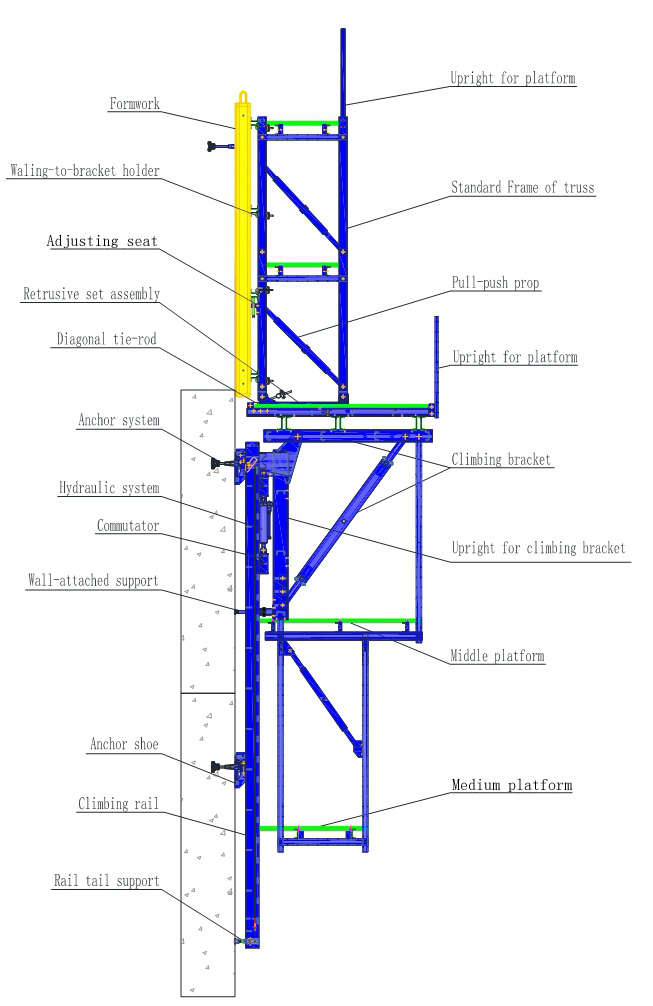

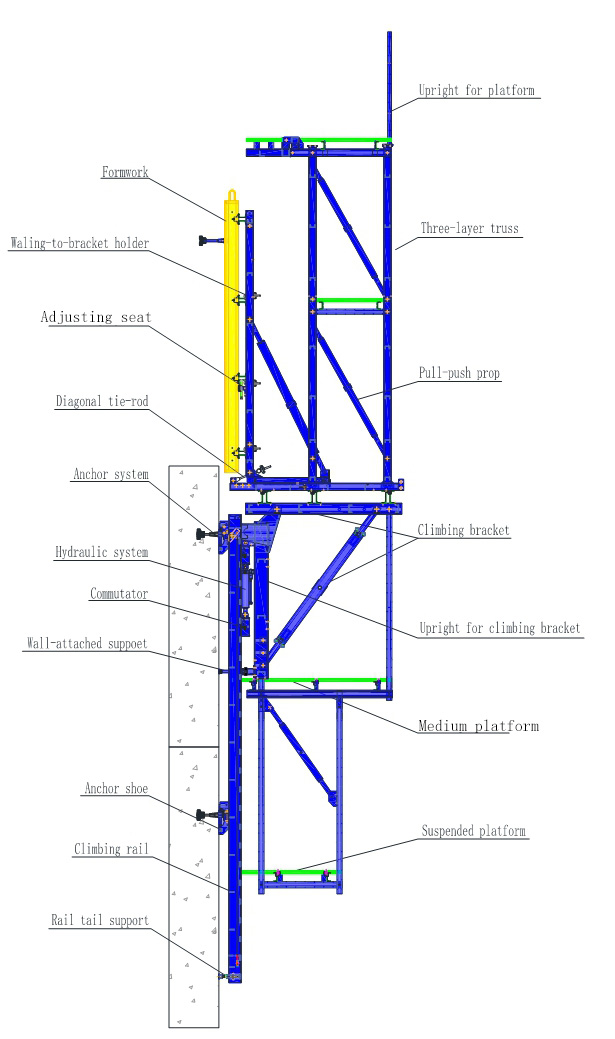

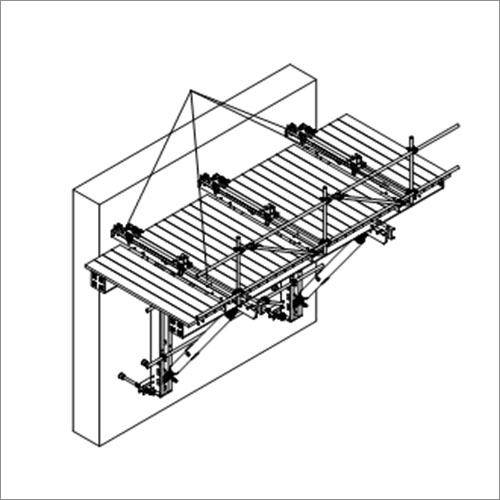

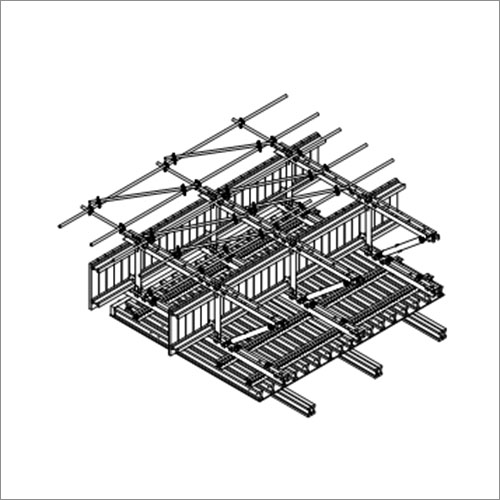

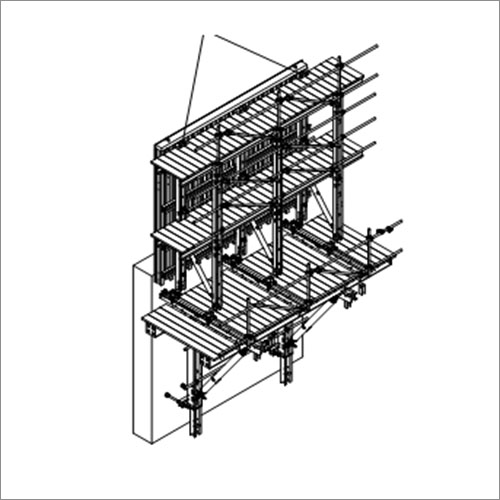

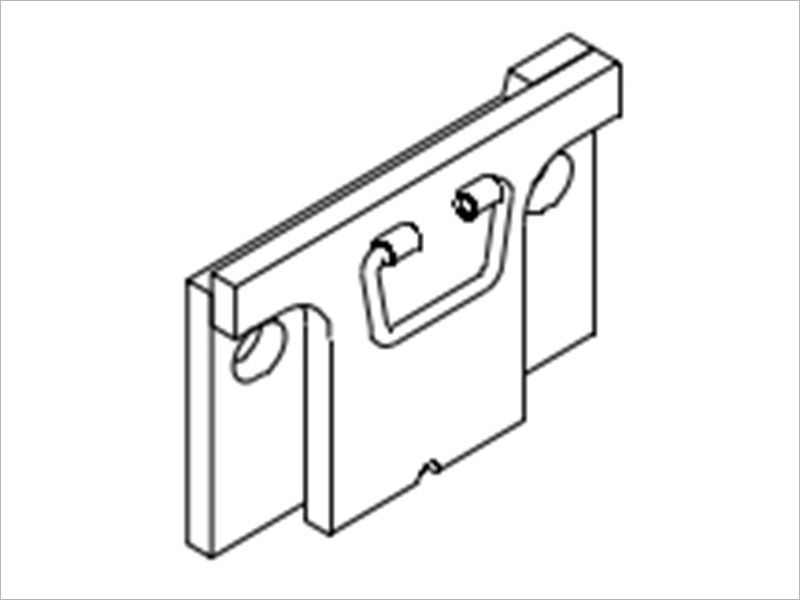

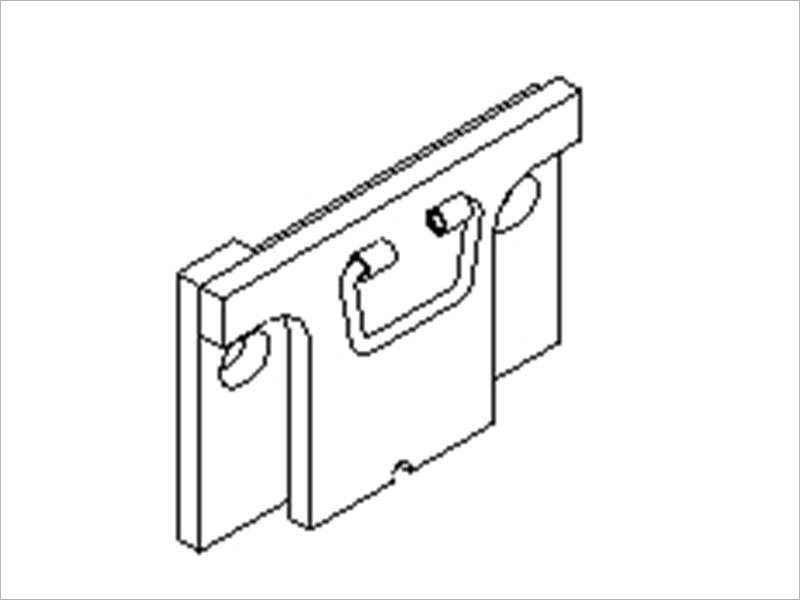

2.Structure diagram of truss type

Composite truss

Separate truss

Main function indicators

1.Construction load:

Top platform ≤4KN/m²

Other platform: 1KN/m²

2.Electronically controlled hydraulic lifting system

Cylinder stroke: 300mm;

Hydraulic pump station flow: n ×2L /min, n is the number of seats;

Stretching speed: about 300mm/min;

Rated thrust: 100KN & 120KN;

Double cylinder synchronization error: ≤20mm

Introduction to systems of hydraulic auto-climbing formwork

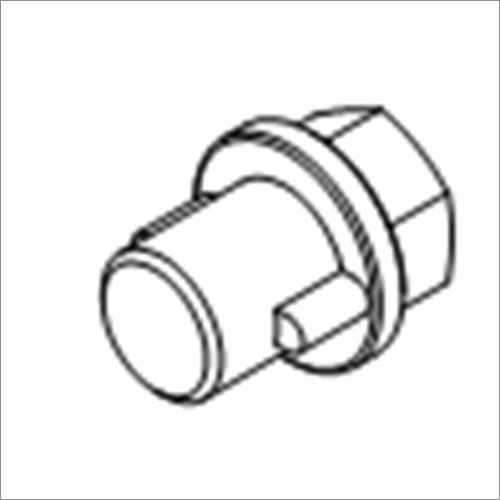

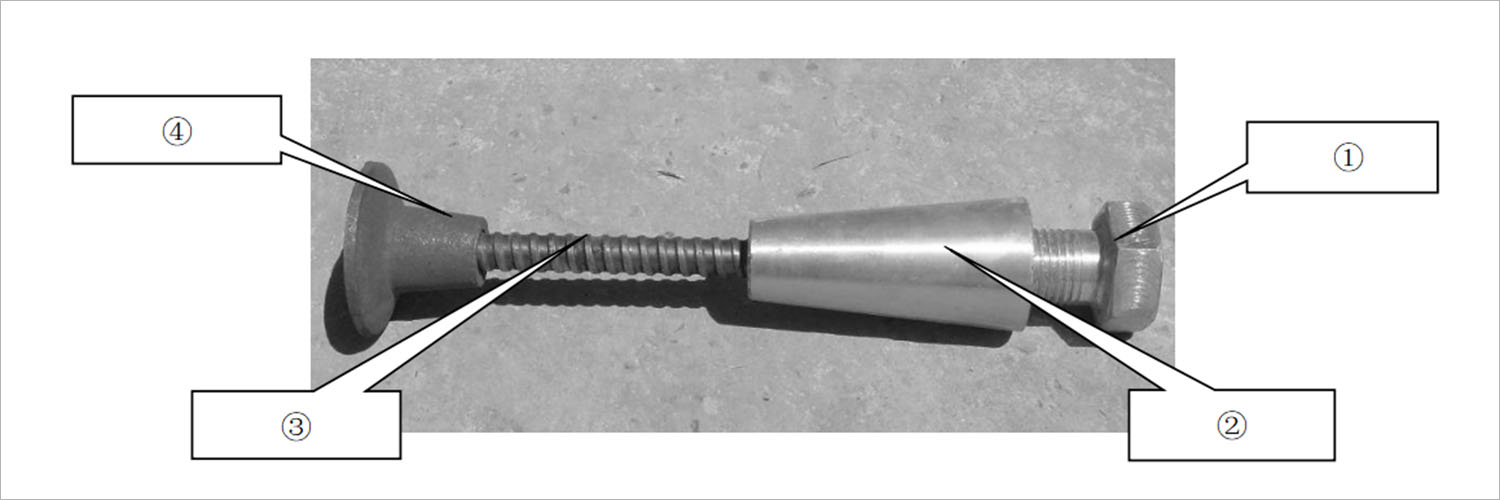

Anchor system

Anchor system is the load bearing system of the whole formwork system. It consists of tensile bolt, anchor shoe, climbing cone, high-strength tie rod and anchor plate. The anchor system is divided into two types:A and B, which can be selected according to requirements.

Anchor system A

①Tensile bolt M42

②Cimbing cone M42/26.5

③High-strength tie rod D26.5/L=300

④Anchor plate D26.5

Anchor system B

①Tensile bolt M36

②Climbing cone M36/D20

③High-strength tie rod D20/L=300

④Anchor plate D20

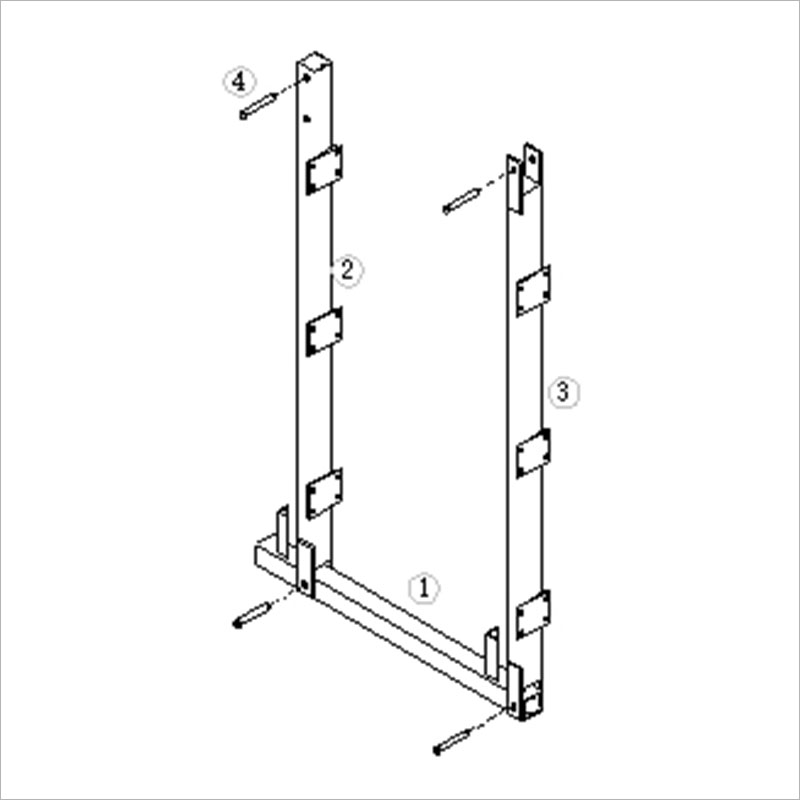

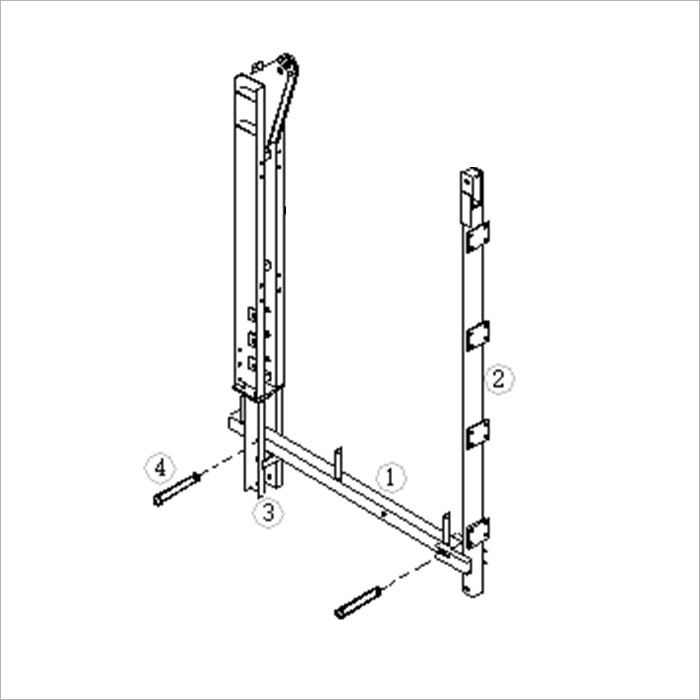

3.Standard components

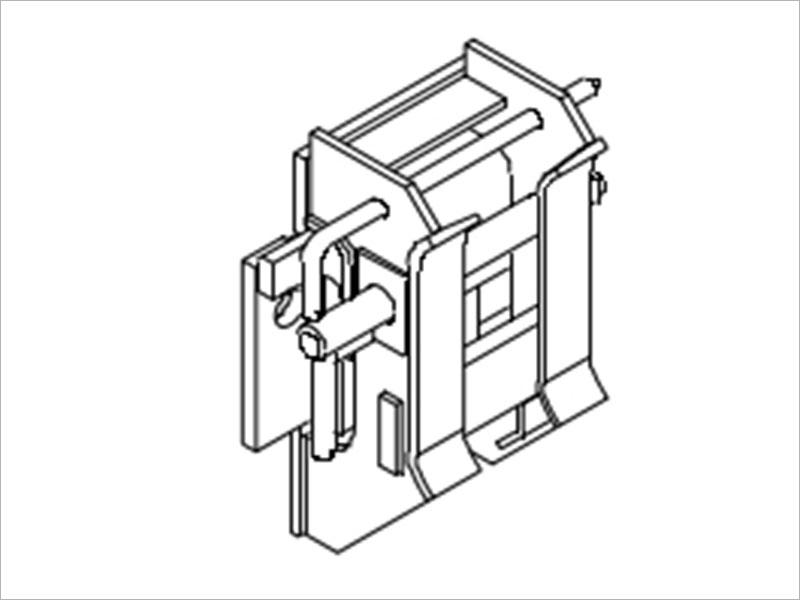

Load-bearing bracket

Load-bearing bracket

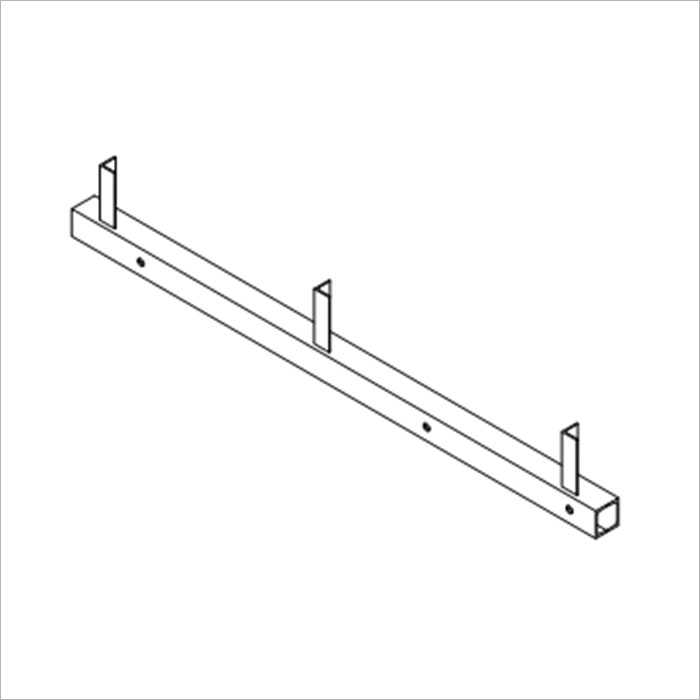

①Cross beam for load-bearing bracket

②Diagonal brace for load-bearing bracket

③Standard for load-bearing bracket

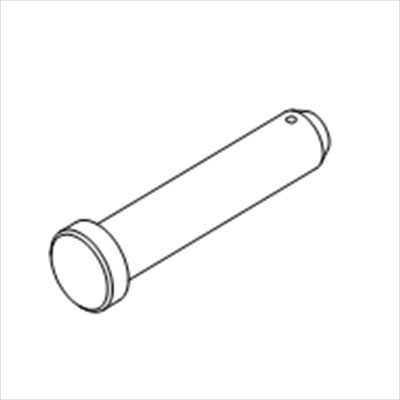

④ Pin

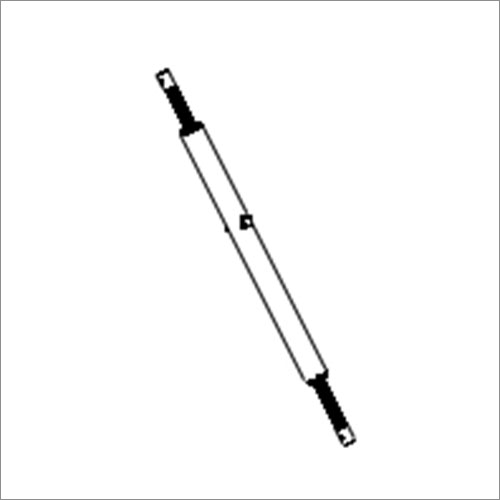

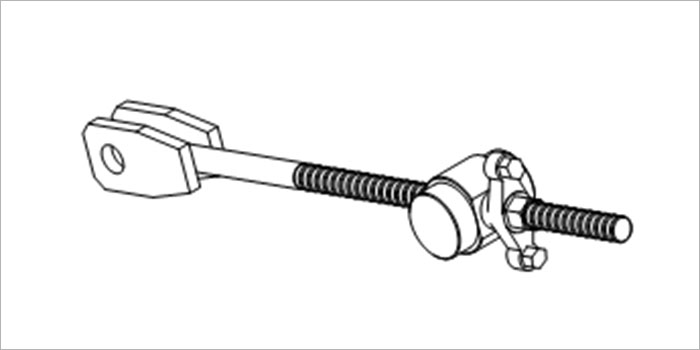

Retrusive set

Retrusive set assembly

Retrusive tie-rod set

Retrusive set

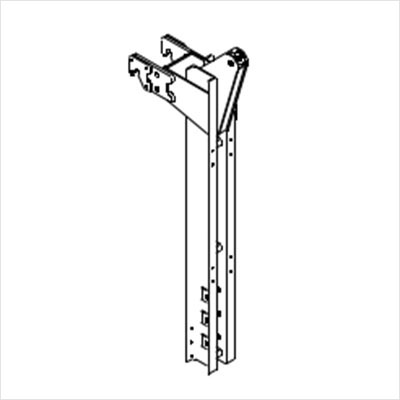

Medium platform

①Cross beam for medium platform

②Standard for medium platform

③Connector for standard

④Pin

Retrusive set

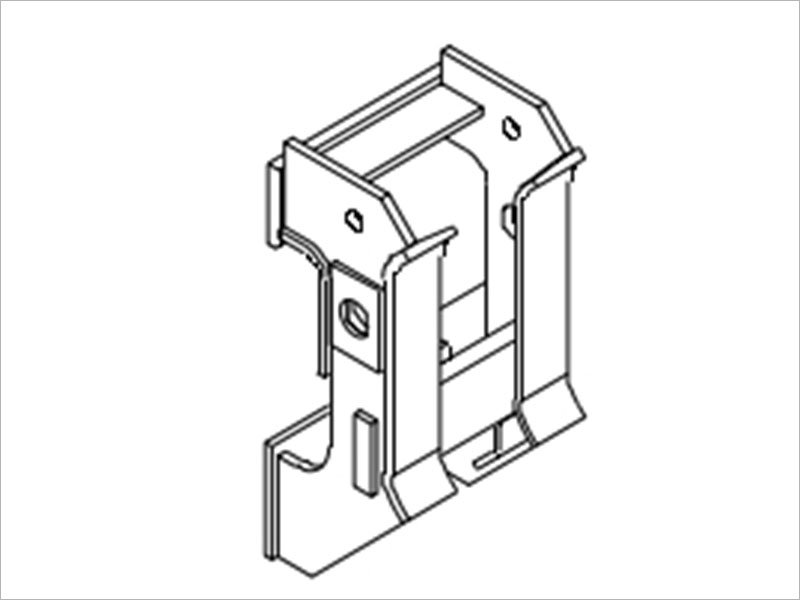

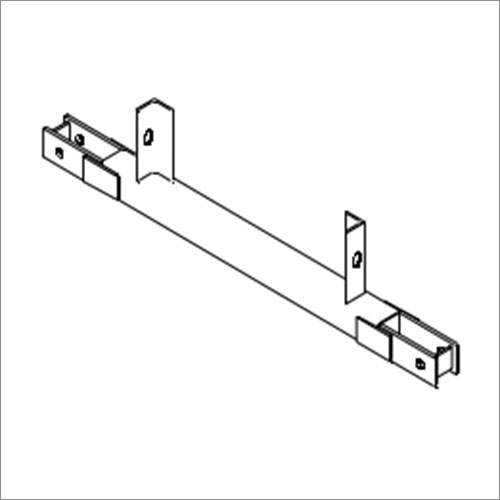

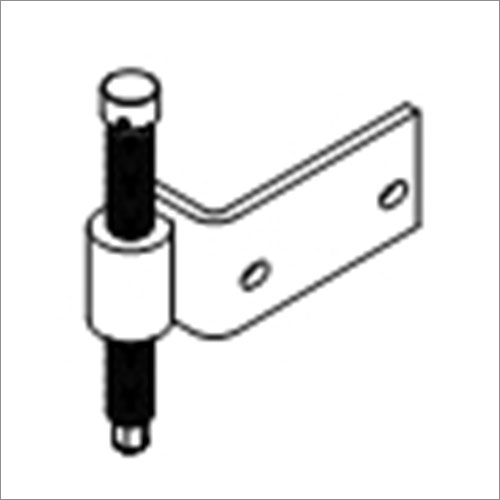

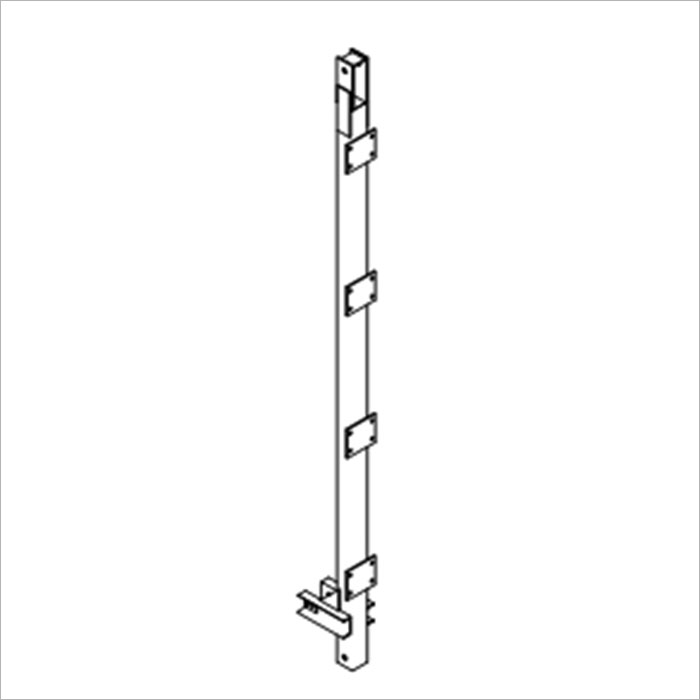

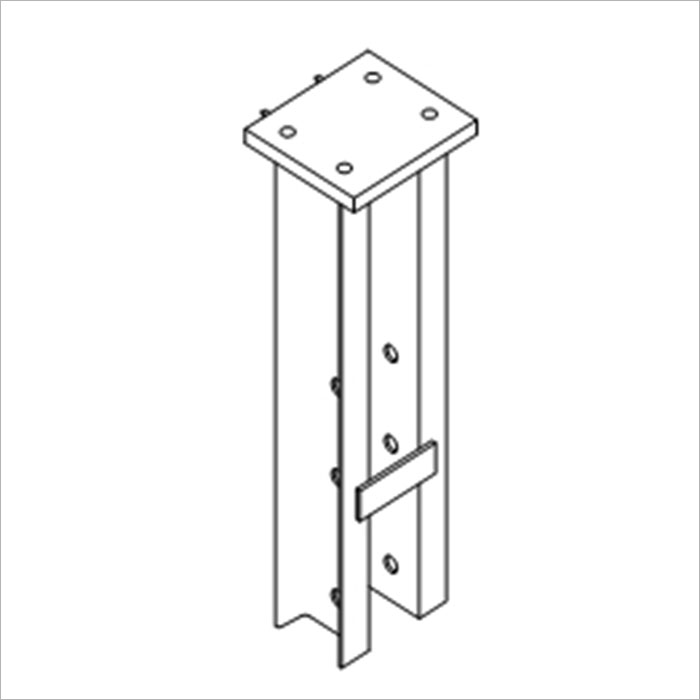

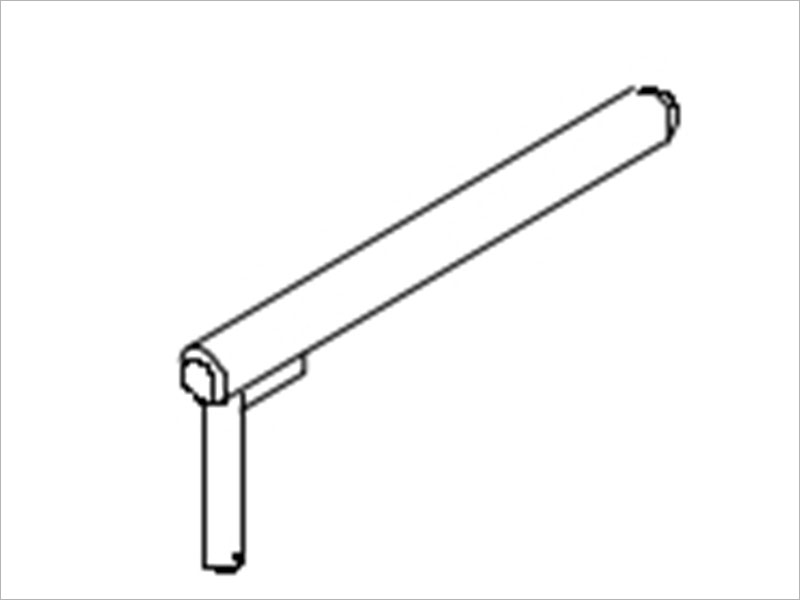

Wall-attached anchor shoe

Wall-attached device

Bearing pin

Safety pin

Wall-attached seat (left)

Wall-attached seat(right)

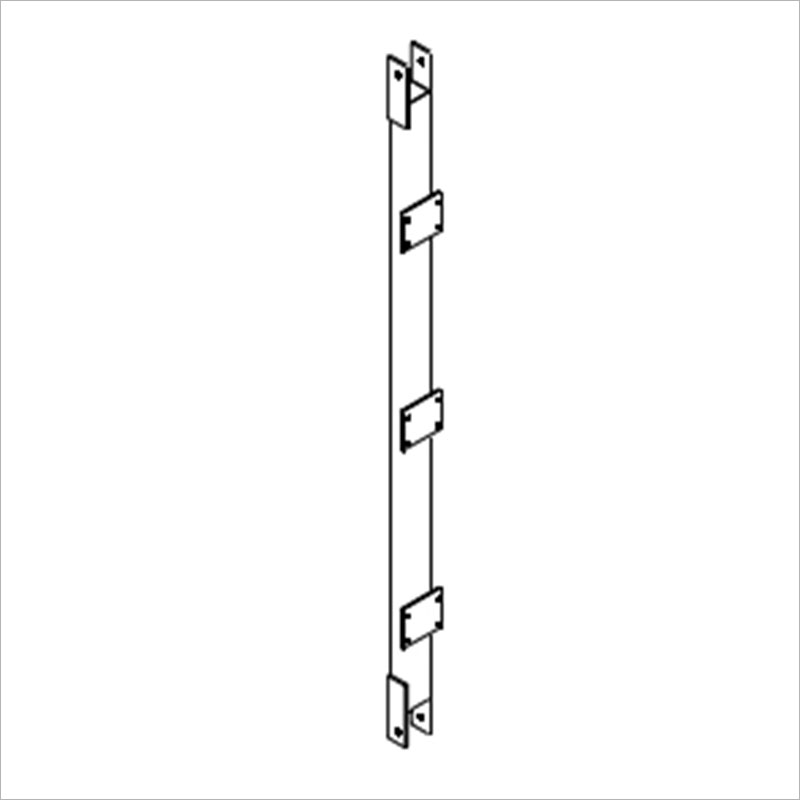

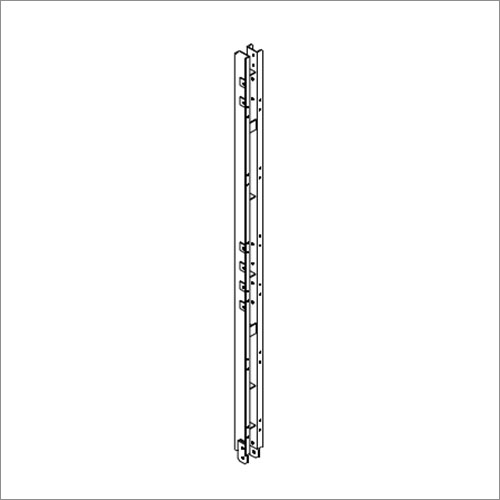

Climbing rail

Suspended platform assembly

①Cross beam for suspended platform

②Standard for suspended platform

③Standard for suspended platform

④pin

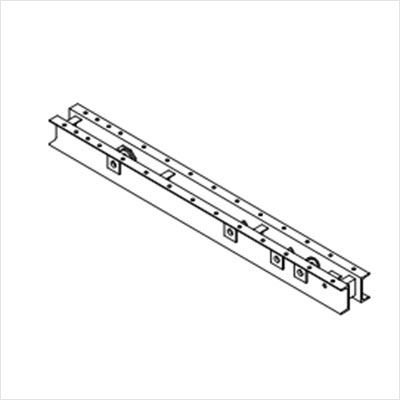

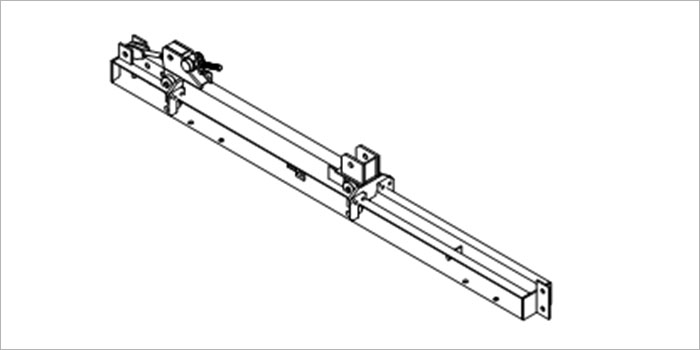

Main waler

Main waler standard section

①Main waler 1

②Main waler 2

③Upper platform beam

④Diagonal brace for main waler

⑤Pin

Accessories

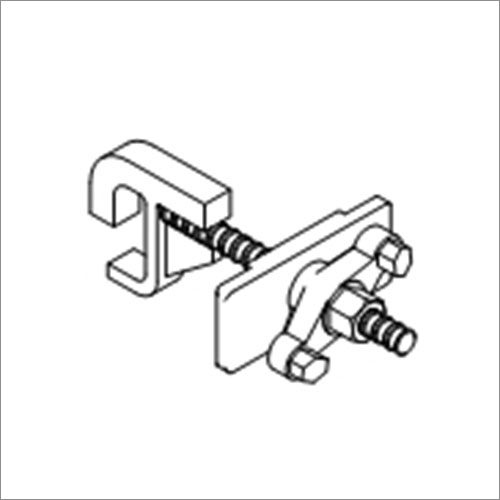

Adjusting seat

Flange clamp

Waling-to-bracket holder

Pin

Taken out tool for climbing cone

Hairpin

Pin for main waler

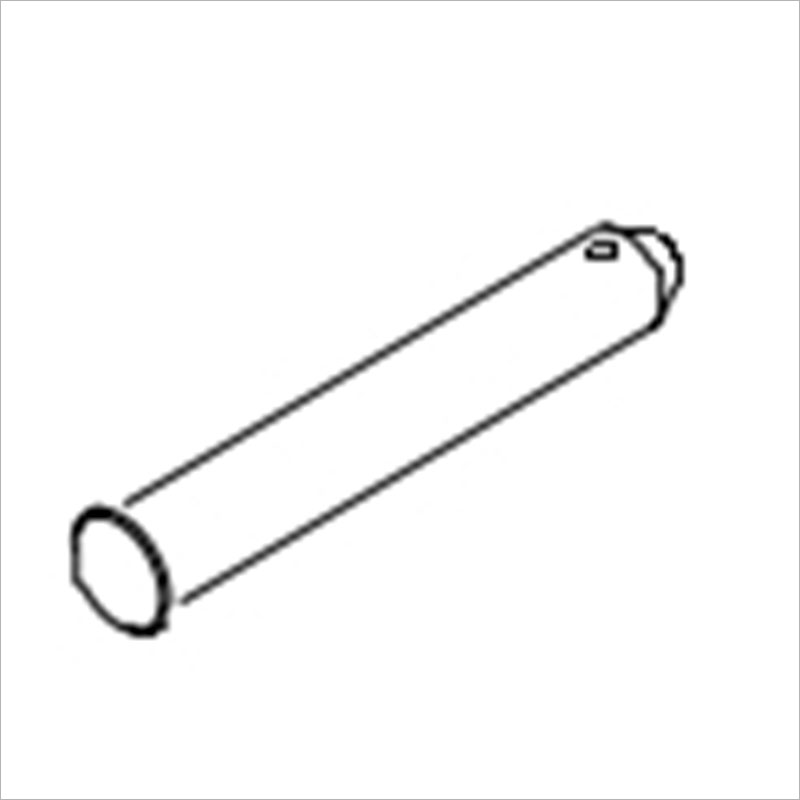

4.Hydraulic system

The hydraulic system consists of commutator, hydraulic system and power distribution device.

The upper and lower commutator are important components for the force transmission between the bracket and the climbing rail. Changing the direction of the commutator can realize the respective climbing of the bracket and climbing rail.

Assembly process

①Bracket assembly

②Platform installation

③Bracket lifting

④Truss assembly and operation platform installation

⑤Truss and formwork lifting

Project Application

Shenyang Baoneng Global Financial Center

Ou Bei Bridge

Product detail pictures:

Related Product Guide:

Using a complete scientific top quality management program, great high-quality and fantastic religion, we win great track record and occupied this area for Online Exporter Cantilever Climbing Formwork - Hydraulic Auto Climbing Formwork – Lianggong , The product will supply to all over the world, such as: New Zealand, Swedish, Bulgaria, We insist on the principle of "Credit being primary, Customers being the king and Quality being the best", we are looking forward to the mutual cooperation with all friends at home and abroad and we will create a bright future of business.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.