OEM/ODM Factory Column Formwork In Middle-East - Plastic Slab Formwork – Lianggong

OEM/ODM Factory Column Formwork In Middle-East - Plastic Slab Formwork – Lianggong Detail:

Product Details

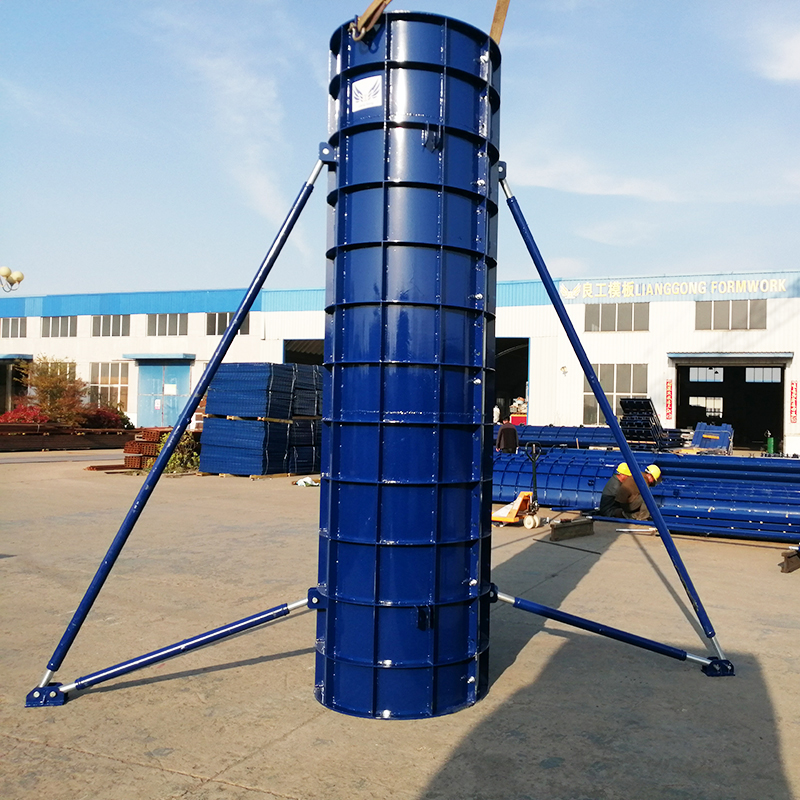

Plastic formwork are suitable to realize concrete columns, pillars, walls, plinths, and foundations directly onsite. Interlocking and modular systems of re-usable plastic formwork are used to build widely variable, but relatively simple, concrete structures. The panels are lightweight and very robust. They are especially suited for similar structure projects and low-cost, mass housing schemes. Their modularity satisfies every construction and planning needs: columns and pillars of different shapes and dimensions, walls and foundations of different thickness and height.

Plastic formwork are very light formworks in comparison with the traditional wood panels. Moreover, the plastic material they are made of allows the concrete not to stick: every element can be easily cleaned just with a little water.

Characteristics

1. Modular and versatile on-site.

2. Patented handles in nylon for an excellent locking of the panels.

3. Easy dismantling and quick cleansing just with water.

4. High resistance(60 kn/m2) and duration of the panels.

Advantages

Flexibility

Freely cuttable and repairable with great nail-holding force.Customizable based on the thickness, dimension, and specific property.Customizable on the shape, such as folding, curling.

Lightweight

Easy moving as density reduced by 50% comparing to the wooden formwork.

Water Resistance

Waterproof composite surface perfectly avoids the issues caused by the humid environment, such as weight increase, warping , deformation, corrosion and so on.

Durability

Turnover is up to X times comparing to most of the plastic formworks, with high temperature resistance and excellent comprehensive mechanical property.

Environmental Protection

Safe and environmental friendly the more plastic process meets international standards.

High quality

Cement resistant surface is easy to clean.Dry wall appearance with smooth surface and good impression

Performance

| Testing | Unit | Data | Standard |

| Water absorption | % | 0.009 | JG/T 418 |

| Shore hardness | H | 77 | JG/T 418 |

| Impact strength | KJ/㎡ | 26-40 | JG/T 418 |

| Flexural strength | MPa | ≥100 | JG/T 418 |

| Elastic modulus | MPa | ≥4950 | JG/T 418 |

| Vicat softening | ℃ | 168 | JG/T 418 |

| Flame retardant | ≥E | JG/T 418 | |

| Density | kg/㎡ | ≈15 | —- |

Product detail pictures:

Related Product Guide:

To continuously increase the administration process by virtue of the rule of "sincerely, good religion and excellent are the base of company development", we commonly absorb the essence of linked goods internationally, and continually build new solutions to fulfill the requires of shoppers for OEM/ODM Factory Column Formwork In Middle-East - Plastic Slab Formwork – Lianggong , The product will supply to all over the world, such as: Danish, Pakistan, Grenada, Each product is carefully made, it will make you satisfied. Our products in the production process have got strictly monitored, because it is only to provide you the best quality, we will feel confident. High production costs but low prices for our long-term cooperation. You can have a variety choices and the value of all types are same reliable. If you have any question, do not hesitate to ask us.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.