OEM manufacturer Concrete Boxing - Plastic Column Formwork – Lianggong

OEM manufacturer Concrete Boxing - Plastic Column Formwork – Lianggong Detail:

Product Details

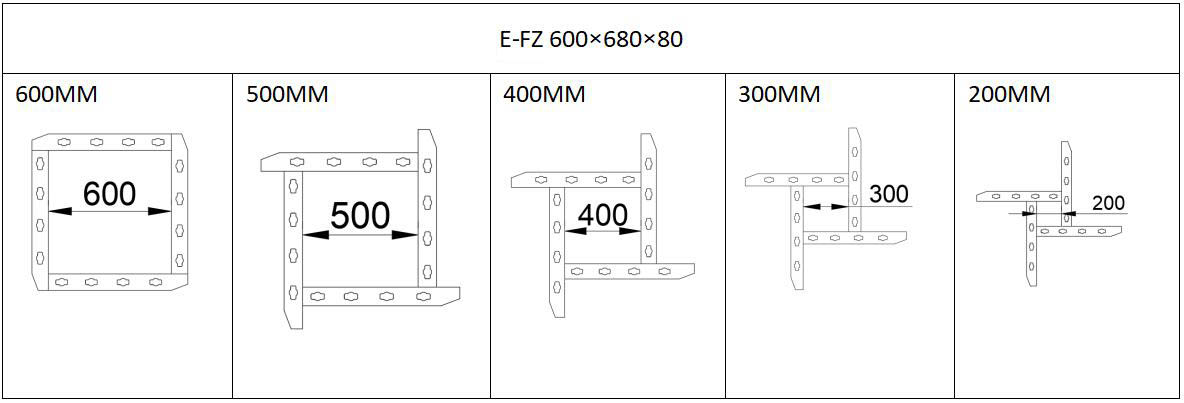

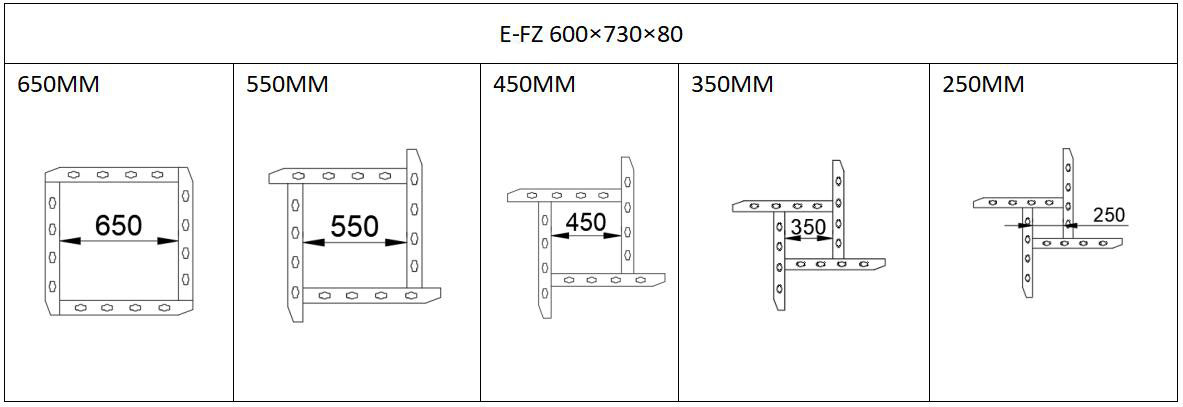

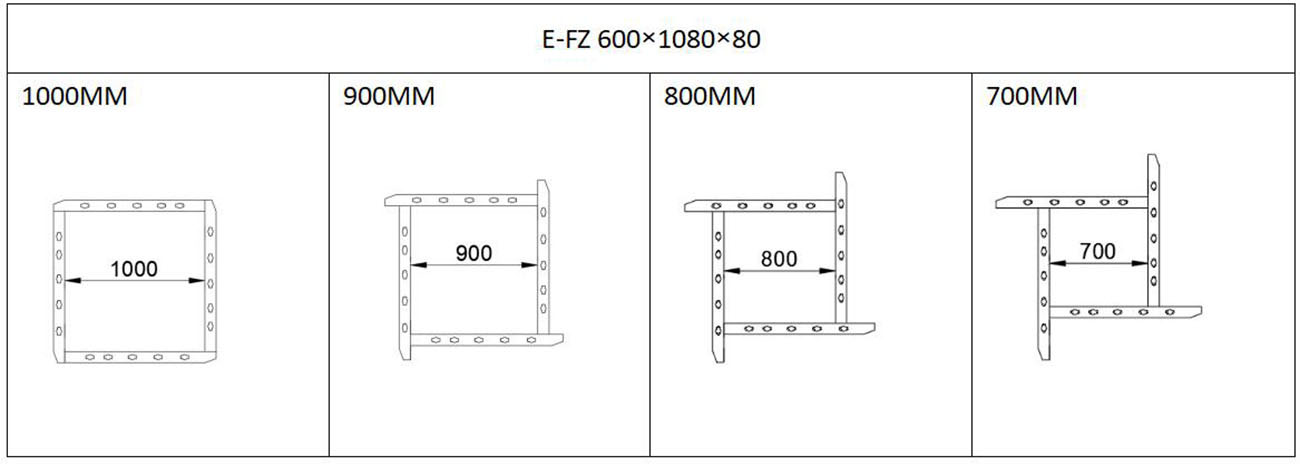

By assembling of the three specifications,square column formwork would complete the square column structure in the side length from 200mm to 1000mm atintervals of 50mm.

Characteristics

* Light weight modular adjustable column panels made from plastic thus can be handled by manual

* Can produce columns with different sizes

* Save budget a great deal compared with other material formwork systems

* Easy erection by a simple 90 degree rotation of erection handle with smooth joints between panels

* Can work under in hot or cold areas

* Durable enough for repeat casting and can be recycled eventually

Product Advantages —— 4E

E1 Economic

A Labor-saving

Common workers can assemble EANTE formwork easily, so the labor cost will be reduced.

B Long cycle times:

Designed service life is 100 times, quality guarantee is 60 times, low average cost and high return rate.

C Accessories decreasing:

LG formwork has the higher strength with the designs of reinforcing rib and mixing glass fiber, so the more square timbers and steel tubes will be reduced in which to be used for reinforcing.

E2 Excellent

A. Good quality :

It has good strength and under the guidance of engineers, it can avoid swollen, deformed or burst mode and flawed

construction quality issues.

B. Good construction quality:

Good perpendicularity and flatness on the concrete surface(less than 5 mm).

C. Good concrete angle:

Good inner, outer and column angle, etc.

E3 Elastic

A. Light-weight:

Easy to carry(15kg/m²) and safe for handlin

B. Easy assembling:

Combined by connecting keys. No iron nail, chainsaw, and other products with potential risk.

C. High universality:

Complete formwork specifications, modular design, free combined and reassemble in the building site,

reconfiguration mode for new projects, no need to return for reprocessing

E4 Environmental

A. Clean and tidy:

The manufacturing and building sites are clean and in a good order.

B. Safe construction:

High strength and light-weight. Much less iron nails, iron wires or other dangerous issues.

C. High universality:

Strive for green manufacturing and green construction field.

Product detail pictures:

Related Product Guide:

As for competitive charges, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such excellent at such charges we have been the lowest around for OEM manufacturer Concrete Boxing - Plastic Column Formwork – Lianggong , The product will supply to all over the world, such as: Georgia, Saudi Arabia, Southampton, We are your reliable partner in the international markets of our products. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad, to create a great future. Welcome to Visit our factory. Looking forward to have win-win cooperation with you.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.