High Performance H20 Timber Beam Formwork - H20 Timber Beam Slab Formwork – Lianggong

High Performance H20 Timber Beam Formwork - H20 Timber Beam Slab Formwork – Lianggong Detail:

Product Details

Table formwork is a kind of formwork that used for floor pouring , used widely in high-rise building , multi-level factory building , underground structure etc. During the construction, after the pouring completion, table formwork sets can be lifted by lifting fork to an upper level and reused, without need to dismantle. Compared with the traditional formwork, it is featured by its simple structure, easy disassembly, and being reusable. It has eliminated the traditional way of slab support system, which consists of cuplocks, eel pipes and timber planks. The construction speeds up obviously, and manpower has been saved greatly.

Standard unit of table formwork

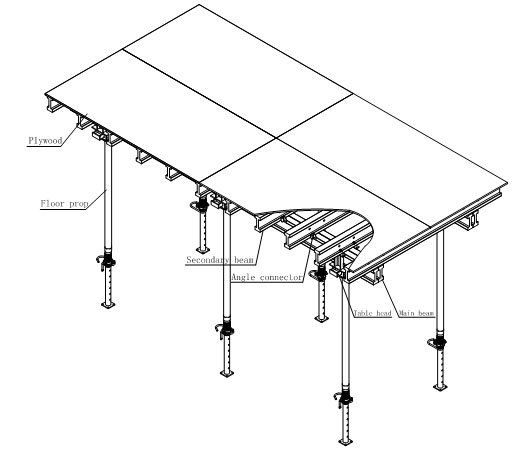

Table formwork standard unit has two sizes: 2.44 × 4.88m and 3.3 × 5m .The structure diagram is as follows:

The flex-table formwork system

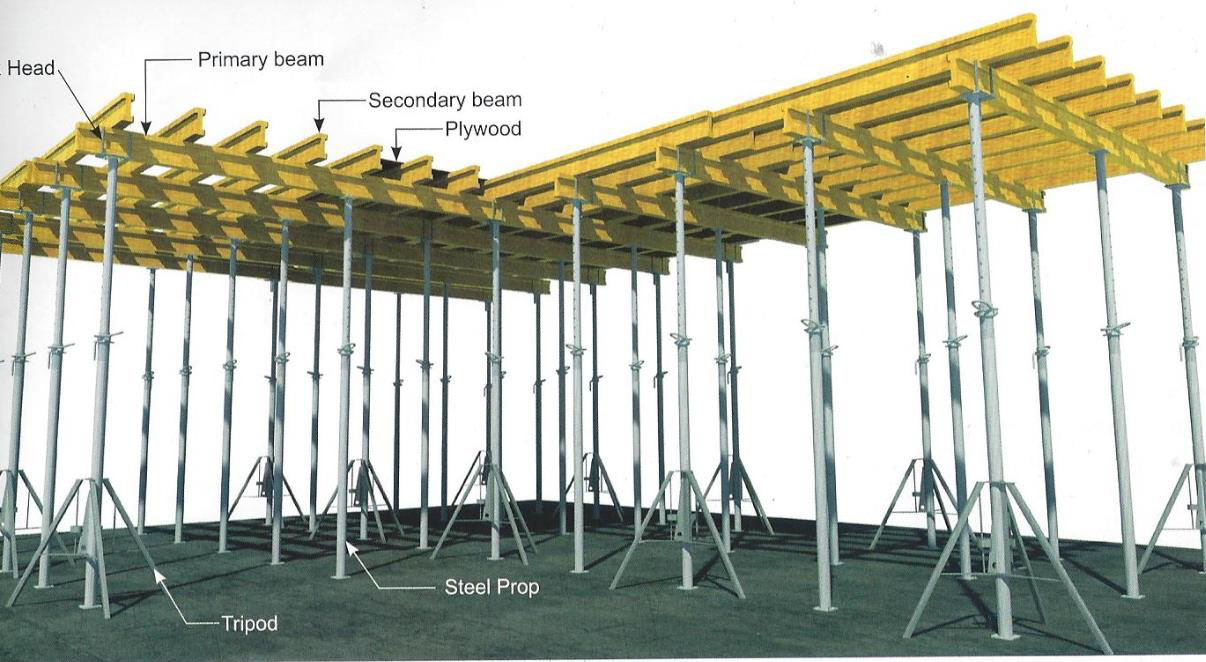

The flex-table formwork system is a formwork for slab concrete pouring in complex floor plan, narrow space. It is supported by steel props or tripods with different support heads, with H20 timber beam as the primary and secondary beams, which are covered with panels. The System can be used for a clear height up to 5.90m.

Characteristics

The most easy and Flex-table Formwork System for all types of slabs, consisting of steel props, tripod, four-way head, H20 timber beam and shuttering panel.

It is mainly used for decking areas around lift shafts and stair cases, also for villa projects or manual handled slab formwork system with limited crane capacity.

This system is fully crane independent.

The H20 timber Beams due to its easy handling, low weight and excellent statically figures its high-grade bonding and protected beam ends with a plastic bumper assures a long duration of life.

This system is simple structure, convenient disassembly and assembly, flexible arrangement and reusability.

Application

Product detail pictures:

Related Product Guide:

To be able to give you benefit and enlarge our business, we also have inspectors in QC Team and assure you our greatest service and products for High Performance H20 Timber Beam Formwork - H20 Timber Beam Slab Formwork – Lianggong , The product will supply to all over the world, such as: Mumbai, United Kingdom, Slovenia, We win many reliable customers by rich experience, advanced equipments, skilled teams, strict quality control and best service. We can guarantee all our products. Customers' benefit and satisfaction are always our biggest goal. Please contact us. Give us a chance, give you a surprise.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.