Excellent quality Track Rod Replacement - PP Hollow Plastic Board – Lianggong

Excellent quality Track Rod Replacement - PP Hollow Plastic Board – Lianggong Detail:

Specification

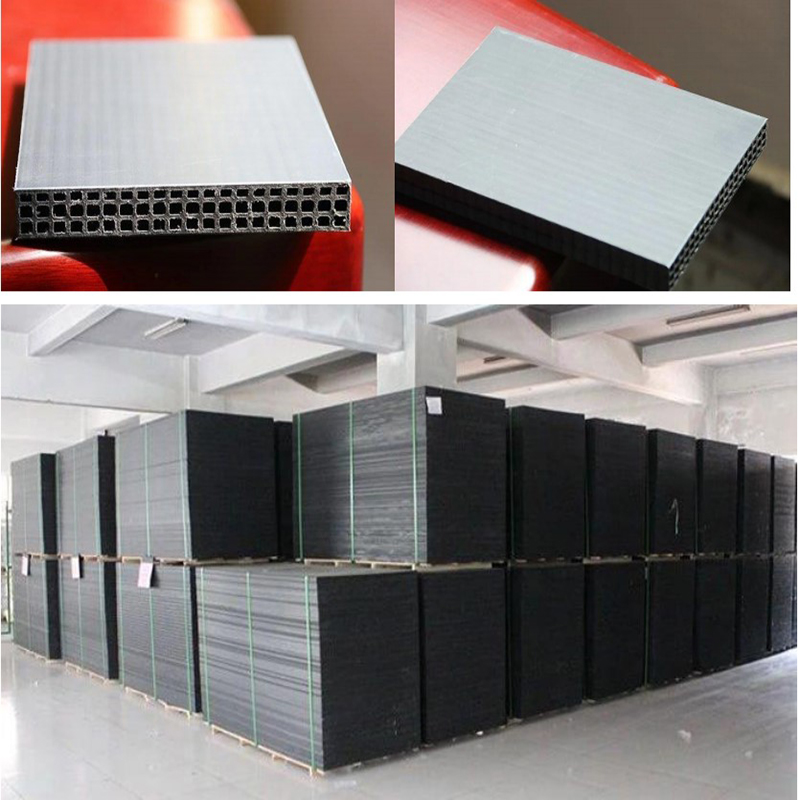

1. Standard specification (mm): 1830*915/2440*1220

2. Standard thickness (mm): 12, 15, 18.

3. Product color: black core/white surface, pure gray, pure white.

4. Non-standard specification can be discussed.

Advantage

1. Reduce costs: reusable more than 50 times.

2. Energy conservation and emission reduction: recyclable.

3. Easy release: no need release agent.

4. Convenient storage: water,sun,corrosion and aging resistance.

5. Easy to maintain: non affinity with concrete, easy to clean up.

6. Lightweight and easy to install:8-10kgs weight per square meter.

7. Fire proof: fire proof hollow formwork can be selected, the fire proof effect reaches V0 level.

Technical Date

|

Test items |

Test method |

Result |

|

|

Bending test |

Refer to JG/T 418-2013,section 7.2.5 & GB/T9341-2008 |

Bending strength |

25.8MPa |

|

Flexural modulus |

1800MPa |

||

|

Softening temperature of VEKA |

Refer to JG/T 418-2013, section 7.2.6 & GB/T 1633-2000 method BO5 |

75.7 °C |

|

Usage Method

1. This product does not need release agent.

2. In the season or area with large temperature difference between early and midnight, the product will show slight thermal expansion and cold shrinkage. When laying the formwork, we should control the seam between the two boards within 1mm, the height difference between adjacent formworks should less than 1mm, and the joints should be reinforced with wood or steel, to prevent the emergence of uneven; if there is a larger seam, sponge or adhesive tape can be attached to the seams.

3. The spacing of the roof timber brace is adjusted by the thickness of the concrete, under normal construction conditions, for 150mm thickness floor, the center distance of the adjacent wood brace should be 200 to 250mm;

The shear wall with a thickness of 300mm and a height of 2800mm, the center distance of the adjacent wood brace should be less than 150mm, and the bottom of the wall should have wood brace;

Depending on the thickness and height of the wall to increase or decrease wood brace spacing;

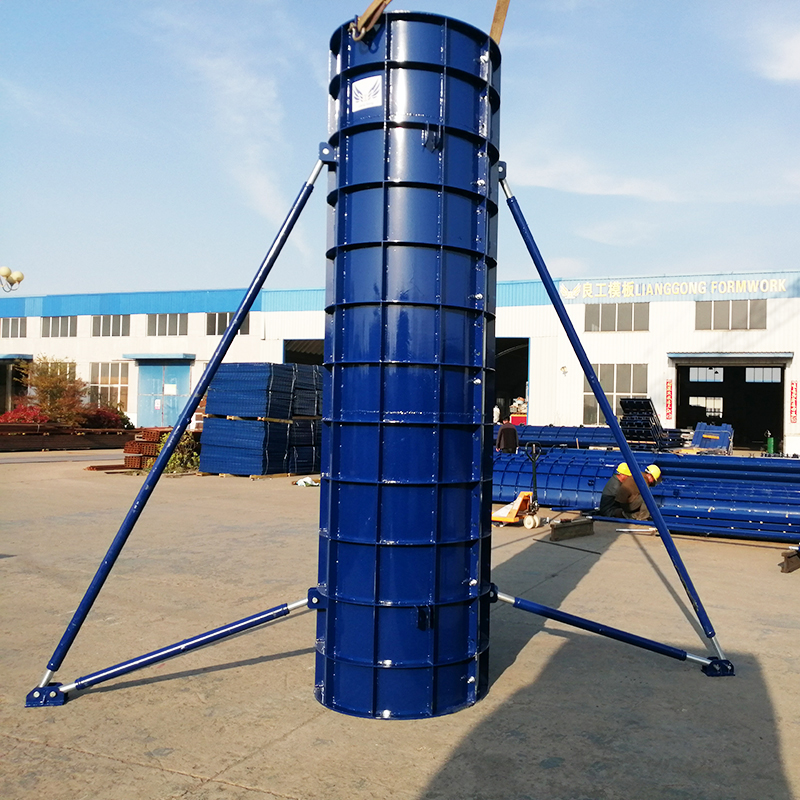

Column width exceed 1 meter must be fixed.

4. The inside corners should have wood brace, for easy connection between the beam and wall.

5. This product can be mixed with plywood of the same thickness.

6. Please use the alloy saw blades with more than 80 mesh to cut the formwork.

7. The use of this product should be disassembled according to the specific location, and avoid unnecessary waste of cutting.

8. strengthen the worker’s safety training before use, improve the awareness of fire prevention, and strictly prohibit smoking at the construction area. It is strictly prohibited to use open fire. Fire blankets should be placed near and below the solder joints before welders operation.

Product detail pictures:

Related Product Guide:

We intention to see quality disfigurement within the creation and supply the ideal support to domestic and overseas buyers wholeheartedly for Excellent quality Track Rod Replacement - PP Hollow Plastic Board – Lianggong , The product will supply to all over the world, such as: Ottawa, Lisbon, Hamburg, Our products are very popular in the word, like South American, Africa, Asia and so on. Companies to "create first-class products" as the goal, and strive to deliver customers with high quality solutions, present high-quality after-sales service and technical support, and customer mutual benefit, create a better career and future!

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!