Are you facing challenges with single-sided wall concrete casting—such as limited construction space, difficult formwork reinforcement, or water leakage risks from wall-through tie rods? Our Lianggong Single-Sided Bracket System is engineered to solve these pain points, delivering unmatched efficiency, waterproof performance, and structural stability for your projects. Designed for versatility and ease of use, this system is the top choice for contractors working on basements, sewage treatment plants, subways, road & bridge slope protection, and power-station low-heat mass concrete structures.

What Are Core Advantages of Our Single-Sided Bracket System?

● 100% Integral Waterproofing: Eliminates wall-through tie rods entirely, ensuring the cast wall remains monolithic and waterproof—no gaps or penetration risks, critical for underground and water-exposed structures.

● High-Capacity Single-Pour Performance: Truss Type supports a maximum one-time casting height of 7.5m, while Diagonal Brace Type reaches up to 4m, adapting to diverse structural height requirements without multiple pours.

● Simplified Construction & Labor Savings: Universal components, easy assembly, and quick disassembly streamline workflows. Reduces formwork handling labor, accelerates project timelines, and cuts down on material waste.

● Superior Structural Stability: Robust load-bearing design effectively resists concrete lateral pressure, preventing formwork deformation or breakage—even in high-pressure casting scenarios. Ensures smooth, honeycomb-free concrete finishes.

● Versatile Compatibility: Works seamlessly with both steel formwork systems and timber beam systems, making it adaptable to various project specifications and existing workflows.

What Are Key Components of Our Single-Sided Bracket System?

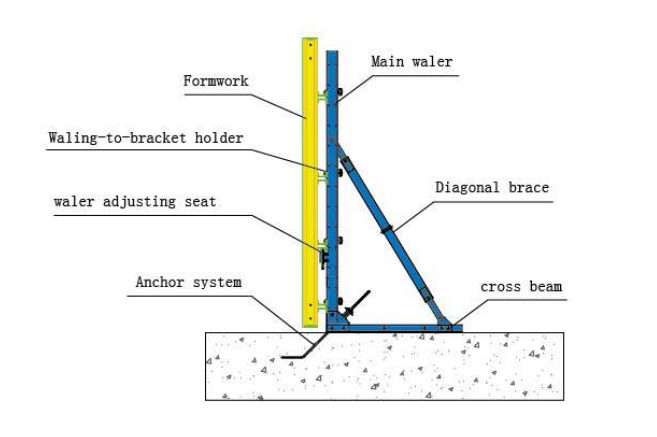

Single-sided bracket system, also known as single-sided wall system, consists of anchor system, formwork system and single-sided bracket system, here are the specific introduction of key components of our single-sided wall system:

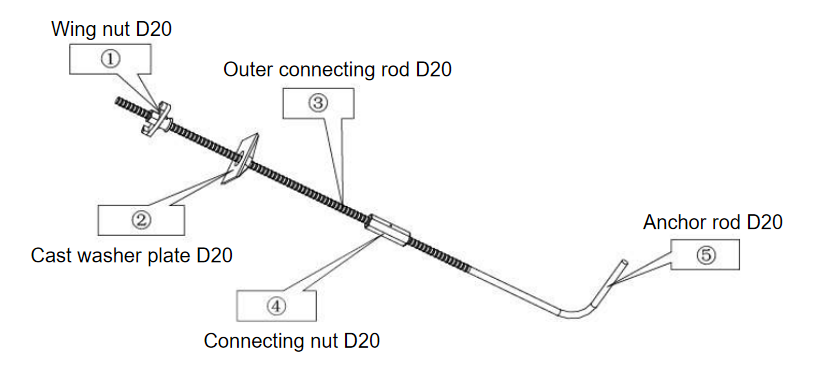

1. Anchor System

The anchor system is the foundation of the bracket’s stability, consisting of Wing nut D20, Cast washer plate D20, Outer connecting rod D20, Connecting nut D20, Anchor rod D20. Engineered to transfer high tensile and shear forces into the structure, it securely bears the weight of the bracket, formwork, and concrete loads—eliminating the need for wall-through tie rods. Wing nut D20, Cast washer plate D20, Outer connecting rod D20, Connecting nut D20 are reusable, cost-effective, and precisely manufactured to ensure reliable anchoring even in demanding construction environments. Installation is straightforward: embed the anchor bolts before pouring the underground layer, then fasten the bracket system for immediate use.

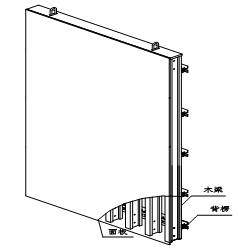

2. Formwork System

Our formwork system is designed for compatibility and performance, working in tandem with the single-sided bracket to deliver flawless concrete results. It supports both steel formwork and timber beam systems, allowing flexibility based on project needs. The formwork system features high-quality plywood panels supported by walers and timber beams to ensure tight sealing against concrete surfaces, preventing grout leakage and joint misalignment. With no wall-through tie rods, the system avoids surface defects, ensuring a smooth, waterproof finish that requires minimal post-construction treatment. It also facilitates easy access for rebar tying and formwork maintenance during the casting process.

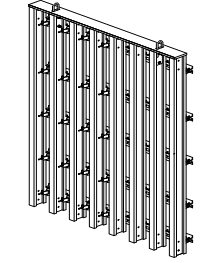

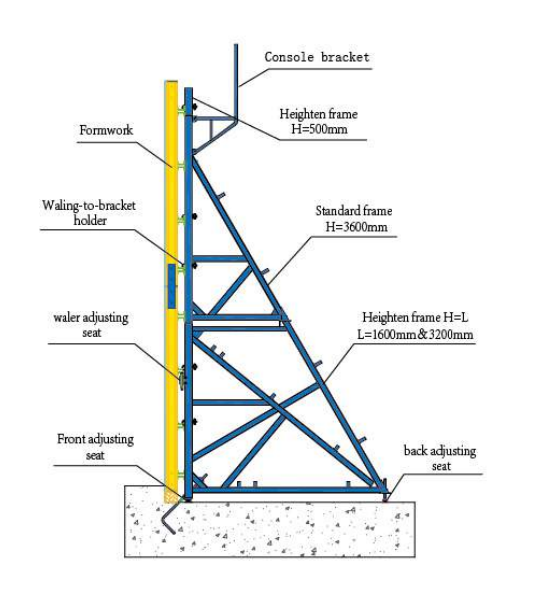

3. Single-Sided Bracket System

Available in two specialized types to meet diverse project requirements, our bracket system combines durability, flexibility, and ease of use:

Truss Type Single-Sided Bracket:

● Maximum One-Time Casting Height: 7.5m, ideal for large-scale structures requiring tall single pours.

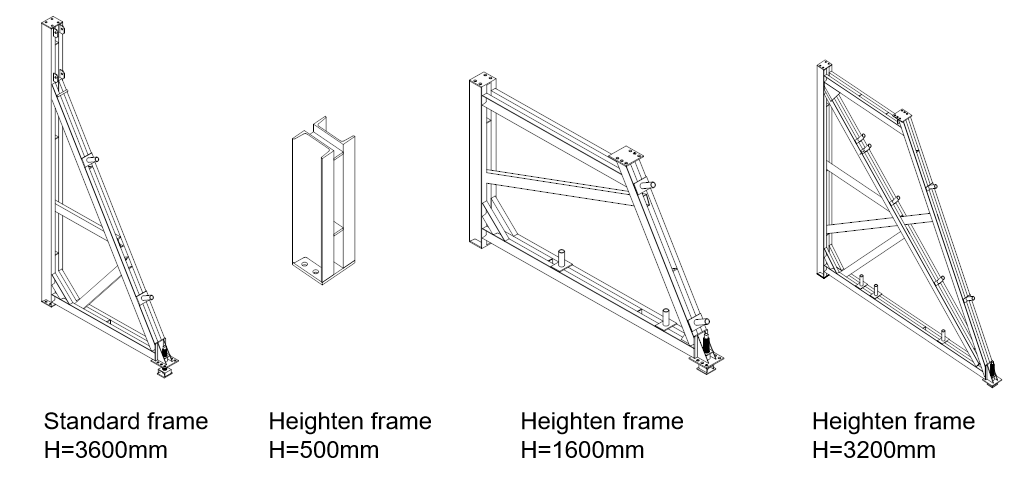

● Modular Design: Composed of 3.6m standard frames and heighten frames (0.5m/1.6m/3.2m), allowing customized configurations for different project heights without extensive modifications.

● Robust Load Bearing: Engineered to withstand high concrete lateral pressure, making it suitable for heavy-load applications like thick retaining walls and power-station mass concrete structures.

Diagonal Brace Type Single-Sided Bracket:

● Maximum One-Time Casting Height: 4m, perfect for mid-rise single-sided walls and projects with space constraints.

● Simplified Structure: Features a lightweight yet sturdy design with easy disassembly and assembly, reducing on-site labor time and transportation costs.

● Convenient Storage: Compact dimensions when disassembled, saving warehouse space and lowering logistics expenses.

What is the Ideal Applications of Our Single-Sided Bracket System?

Our Single-Sided Brace Frame System is trusted for a wide range of projects:

● Basement outer walls (where space limits traditional formwork)

● Sewage treatment plants (waterproof requirements)

● Subway tunnels and stations

● Road & bridge slope protection

● Power-station low-heat mass concrete structures

● Retaining walls and single-sided concrete walls

Why Choose Lianggong Single-Sided Bracket System?

Lianggong’s Single-Side Bracket is built on decades of engineering expertise, focusing on solving real-world construction challenges. We prioritize quality, efficiency, and cost-effectiveness—delivering a product that not only meets but exceeds global construction standards. With universal components, waterproof performance, and two versatile bracket types, our system adapts to your project’s unique needs while reducing labor, time, and material costs.

Ready to elevate your single-sided wall construction? Click to explore detailed case studies, technical drawings, and customized quotes. Let’s build stronger, drier, and faster—together.

How to Contact Us?

Company: Yancheng Lianggong Formwork Co., Ltd.

Website: https://www.lianggongformwork.com https://www.fwklianggong.com https://lianggongform.com

Email: sales01@lianggongform.com

Tel: +86-18201051212

Address: No.8 Shanghai Road, Jianhu Economic Development Zone, Yancheng City, Jiangsu Province, China

Post time: Nov-26-2025