Are you looking for a scaffolding system that combines unbeatable stability, quick assembly, and long-lasting durability for your construction projects? Our Lianggong Ring Lock Scaffolding System stands out as a top-tier vertical support, designed to meet the demands of high-rise buildings, bridges, stadiums, industrial facilities, and more. Available in 48mm (B-type) and 60mm (A-type) systems, it adheres to international standards like EN 1004 and OSHA, delivering reliability that contractors worldwide trust.

What Key Benefits Make Our Ring Lock Scaffolding Stand Out?

● Rapid & Easy Assembly: Modular design with intuitive interlocking components cuts down assembly time drastically. No complex tools are needed—components lock securely via positive engagement pins, reducing labor costs and accelerating project timelines.

● Superior Stability & Load-Bearing Capacity: Innovative rosette joint design (8 holes: 4 small for ledgers, 4 large for diagonal braces) ensures stable connections.

● Long-Lasting Durability: High zinc coating protects against corrosion, extending the lifespan of scaffolding ring lock system and keeping it clean and visually appealing for repeated use across projects.

● Dual-System Versatility: Choose the 48mm B-type for residential construction and interior renovations, or the 60mm A-type for heavy-duty support in bridge engineering and large-scale infrastructure—adapting seamlessly to diverse project needs.

● Compliance with Global Standards: Meets strict safety regulations including JGJ231-2010, GB 51210-2016, and JGJ59-2011, ensuring your project stays compliant while prioritizing worker safety.

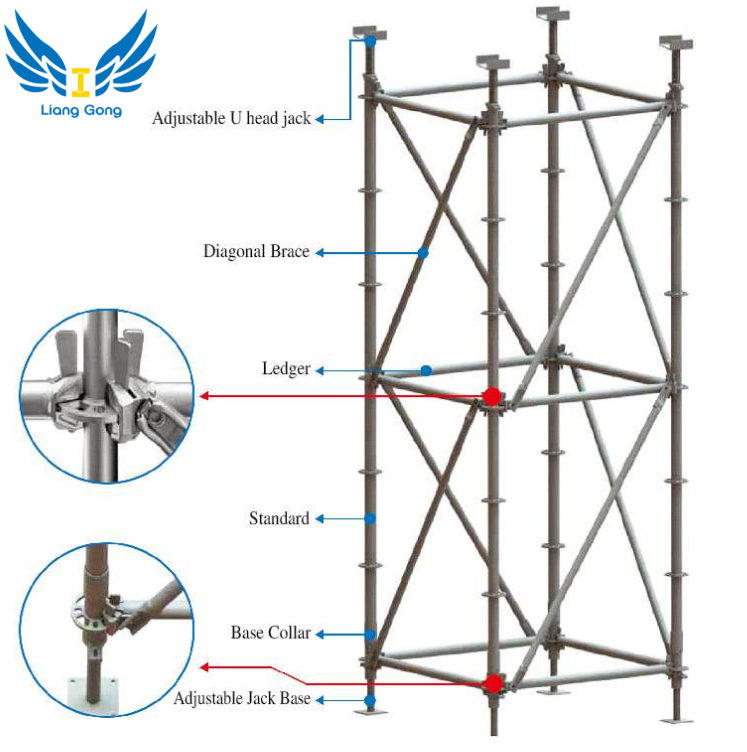

What Are Core Components of Our Ring Lock Scaffolding?

Every part of our scaffolding ring lock is precision-engineered for seamless compatibility, maximum stability, and long-lasting performance—working together to form a reliable framework for any construction scenario. Below are the key components that define efficiency and safety of ring lock scaffold:

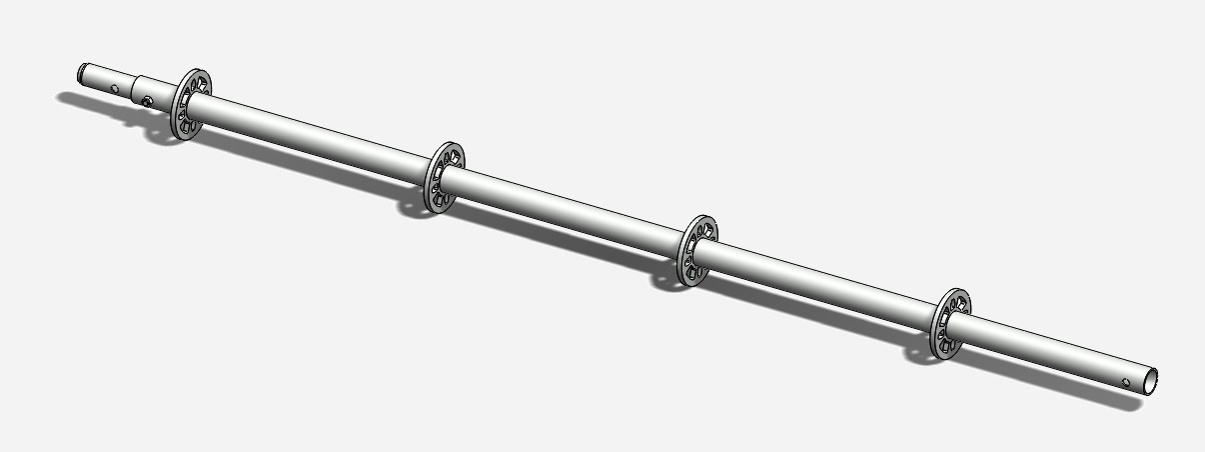

1. Standard

As the backbone of the ring lock scaffolding system, the standard, also called upright, bears the core load of ring lock scaffolding and serves as the connection hub for all horizontal and diagonal components. It is welded with a universal 8-hole rosette (4 small holes for ledgers, 4 large holes for diagonal braces) to ensure secure, multi-directional assembly. We offer two specifications to match project needs:

● 48mm diameter (B-type): Designed for light-to-medium loads, ideal for residential construction, interior renovations, and low-rise projects.

● 60mm diameter (A-type): Built for heavy-duty support, perfect for bridges, high-rises, and industrial facilities that require superior load-bearing capacity.

2. Ledger

The ledger is the horizontal load-distribution component that connects adjacent standards via the rosette’s small holes. Crafted from high-strength low-alloy steel, it forms the horizontal framework of scaffolding ring lock system, ensuring even weight transfer across the structure. Its modular design allows quick interlocking with standards—no complex tools needed—speeding up assembly while maintaining rigidity, even in large-span setups (e.g., stadiums or bridge decks).

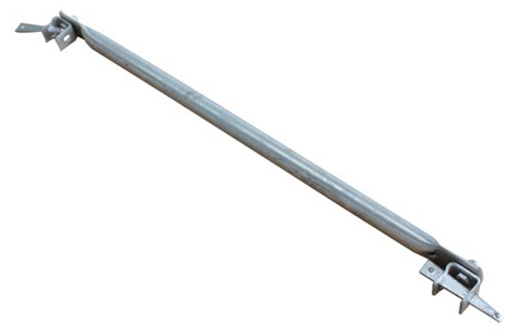

3. Diagonal Brace

Critical for lateral stability and anti-sway performance, the diagonal brace links standards through the rosette’s large holes, creating a triangular support structure that resists horizontal forces (e.g., wind, construction vibration). Like ledgers, it is made from low-alloy steel with a corrosion-resistant zinc coating, ensuring durability in outdoor or humid environments (e.g., highway bridges, sewage treatment plants). It is especially vital for tall scaffolding (high-rises) or uneven terrain, preventing structural deformation during heavy-load operations.

4. Jack Base

The jack base, as known as screw jack foot, is the adjustable foundation component that sits at the bottom of each standard, solving the challenge of uneven construction sites. It features a threaded rod and cast jack nut, allowing precise height adjustment to level the scaffolding ring lock— whether on sloped ground, uneven concrete, or sites with small elevation differences. Made from high-strength steel, it distributes the standard’s load evenly to the ground, reducing pressure on the foundation and preventing sinking. It is fully compatible with both 48mm and 60mm standards, adapting to diverse project bases.

5. U Head Jack

Mounted at the top of standards, the U head is the load-bearing and height-fine-tuning component that directly supports formwork, beams, or structural elements. Its U-shaped groove securely holds timber beams, steel joists, or concrete formwork, preventing slippage during pouring or assembly. Like the jack base, it includes an adjustable threaded rod—enabling micro-height adjustments (up to standard limits) to ensure formwork is perfectly level, critical for achieving smooth concrete finishes in high-precision projects (e.g., industrial floors, bridge piers).

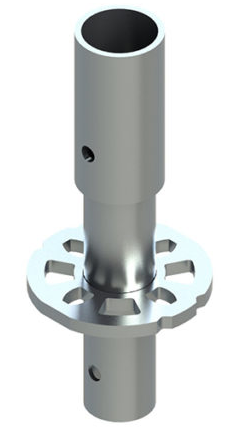

6. Base Collar

The base collar is a protective and stabilizing accessory installed between the jack base and the standard’s bottom end. Made from durable steel with a zinc coating, it is a small but essential component for long-term reliability of scaffolding ring lock system. Its key roles include:

● Alignment: Ensures the standard stays vertically centered on the jack base, preventing tilting or misalignment during assembly and load-bearing.

● Protection: Shields the bottom of standard from corrosion, impact, or concrete splatter— extending the component’s lifespan, especially in outdoor or wet construction environments (e.g., subway tunnels, basement builds).

● Reinforcement: Adds a extra layer of connection rigidity between the standard and jack base, reducing wobble and enhancing overall structural stability.

What Are Applications of Our Ring Lock Scaffolding?

● High-Rise Buildings: The stability and adjustability of ring lock scaffolding system make it ideal for constructing tall buildings where precision and safety are critical.

● Bridges and Highways: Used extensively in the construction of bridges and highways, the ring lock scaffold provides the necessary support and stability for large-scale infrastructure projects.

● Sports Stadiums and Arenas: The modular design allows for easy adaptation to the complex structures of sports facilities, ensuring efficient construction processes.

● Industrial Facilities: The durability and load-bearing capacity of scaffold ring lock make it perfect for constructing industrial complexes and warehouses.

Why Choose Lianggong Ring Lock Scaffolding?

As a leading provider of formwork and scaffolding, we don’t just deliver products—we deliver complete peace of mind. Our ring lock scaffolding is backed by comprehensive service, including installation training, on-site oversight, and timely repairs. We offer personalized guidance to help you select the right system (48mm or 60mm) for your project, ensuring you get the best value, safety, and efficiency.

Ready to elevate your construction project with a ring lock scaffolding system that works as hard as your team? Click to explore detailed case studies, technical drawings, and customized quotes. Let’s build safer, faster, and smarter—together.

How to Contact Us?

Company: Yancheng Lianggong Formwork Co., Ltd.

Website: https://www.lianggongformwork.com https://www.fwklianggong.com https://lianggongform.com

Email: sales01@lianggongform.com

Tel: +86-18201051212

Address: No.8 Shanghai Road, Jianhu Economic Development Zone, Yancheng City, Jiangsu Province, China

Post time: Nov-28-2025