When it comes to construction projects, finding reliable, efficient, and durable vertical support equipment is crucial for ensuring structural safety, reducing working time, and optimizing project costs. Lianggong Steel Prop stands out as a top-tier choice for construction professionals worldwide, offering unmatched load capacity, flexibility, and ease of use. Designed to adapt to any shaped slab formwork and streamline on-site operations, our steel props are engineered to meet global standards and exceed project expectations—whether for residential builds, commercial complexes, or heavy-duty infrastructure.

What Makes Our Steel Prop the Best Choice for Construction?

● Exceptional Load-Bearing Capacity: Built with high-yield steel, our steel prop delivers robust performance—with maximum working loads ranging from 15KN (Universal 60/48) to 30KN (Heavy Duty AEP-30). Tested by nationally authorized organizations, the basic load capacity exceeds 15KN, ensuring structural stability even under immense stress.

● Wide Adjustable Height Range: Catering to diverse project needs, our props offer adjustable heights from 1400mm to 5500mm. Whether you’re working on low-rise renovations or high-rise slab support, the flexible adjustment (via precision-threaded outer tubes) lets you fine-tune heights with ease.

● Easy Installation & Operation: Designed for efficiency, each steel prop can be erected by a single person—slashing labor time and reducing project costs.

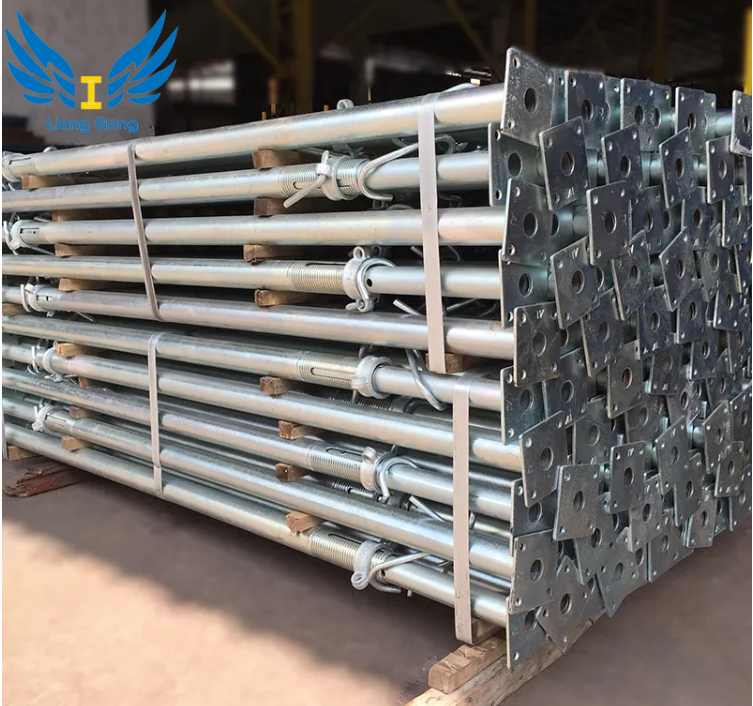

● Space-Saving & Cost-Effective: Compact in size, our steel props are easy to store and transport, minimizing logistics hassle. Their durable construction ensures repeated use across projects, delivering long-term value without compromising performance.

● Versatile Surface Treatments: Choose from multiple surface finishes—hot-dip galvanization, electro-galvanization, or dip coating—to suit harsh construction environments, ensuring corrosion resistance and extended service life.

What Are Our Core Steel Prop Ranges?

We offer three specialized steel prop series, each engineered to meet specific load and application requirements:

| Specification | Working Load | Outer Tube | Inner Tube | Support Height |

| AEP-30 | 30KN | 76.1×2.6mm | 63.5×3.9mm | 1450mm~4500mm |

| AEP-20 | 20KN | 76.1×2.6mm | 63.5×2.6/2.9mm | 1450mm~5500mm |

| 60/48 | 15KN | 60×3mm | 48×3.5mm | 1400mm~5500mm |

What Are Core Components of Our Steel Prop?

Every part of our steel prop is precision-engineered to work in harmony—blending durability, safety, and ease of use to ensure reliable vertical support for any construction scenario. Below are the key components that define its performance and adaptability:

1. Top Plate

As the load-bearing interface between the steel prop and upper structures (e.g., slab formwork, timber beam), the top plate distributes vertical pressure evenly to prevent localized stress damage.

● Design: Standard 120×120mm size (thickness varies by model: 6mm for Universal 60/48, 8mm for Heavy Duty AEP-20/AEP-30) to ensure wide contact with formwork components.

● Function: Secures the prop to timber beams or formwork accessories, avoiding slippage during concrete pouring or heavy-load operations. Its flat, rigid surface guarantees stable load transfer, a critical feature for maintaining structural integrity in high-stress scenarios.

2. Inner Tube

The adjustable vertical core of the steel prop, the inner tube enables height flexibility.

● Material & Design: Crafted from high-yield steel (thickness: 3.5mm for Universal 60/48, 2.6–3.9mm for Heavy Duty AEP-20/AEP-30) with precisely spaced holes (13.5mm for 60/48, 17.5mm for AEP series) along its length. These holes work with the G pin to lock the desired height.

● Function: Slides inside the outer tube to adjust the prop’s total height (1400mm–5500mm, depending on the model). Its compatibility with standard scaffold tubes and couplers also allows for easy bracing—enhancing lateral stability in tall or large-span setups.

3. Outer Tube

The structural backbone of the steel prop, the outer tube houses the adjustment mechanism and bears the core load of the system.

● Material & Design: Made from thick-walled low-alloy steel with a precision-rolled thread section (205mm for 60/48, 230mm for AEP series) on its upper end.

● Function: The threaded section pairs with the adjusting nut for fine height tuning (critical for leveling slab formwork), while the tube’s rigid construction ensures it withstands up to 30KN of vertical load (AEP-30 model) without bending or deformation. The rolled thread retains the tube’s full wall thickness, maximizing strength compared to cut-thread designs.

4. G Pin

The safety locking component that secures the inner and outer tubes at the desired height, preventing accidental slippage during use.

● Design: High-strength steel pin (diameter: 12mm for 60/48, 16mm for AEP-20/AEP-30) with a simple, easy-to-insert design—no complex tools required for installation.

● Function: After adjusting the inner tube to the target height, the G pin is inserted through aligned holes in the inner and outer tubes, locking the two components in place. Its robust construction ensures it resists shear forces, even under maximum load—eliminating the risk of height drift that could endanger formwork or workers.

5. Adjusting Nut

The fine-tuning and load-locking component that works with the outer tube’s threads to refine height and secure the prop’s position.

● Design: Adjusting nut with a specialized side hole—this allows easy turning even when the prop’s handle is close to walls or tight spaces (e.g., narrow stairwell shafts). It is heat-treated for wear resistance, ensuring smooth operation across repeated uses.

● Function: Two key roles: 1) Fine adjustment: Twists along the outer tube’s threads to tweak height by small increments (perfect for leveling uneven formworks); 2) Load locking: Once the desired height is set, the nut is tightened to distribute load evenly between the inner and outer tubes.

6. Base Plate

The foundation component that anchors the steel prop to the ground or lower structures, the base plate prevents the prop from sinking into soft surfaces and balances the entire support system.

● Design: Matches the top plate’s 120×120mm dimensions for consistent load distribution, with corrosion-resistant finishes (painted or galvanized) to withstand damp construction environments.

● Function: Spreads the prop’s downward load across a larger area, protecting the ground from indentation. For uneven terrain, it provides a stable base to keep the prop vertically aligned—avoiding tilting that could compromise safety.

What Are Ideal Applications of Our Steel Prop?

Lianggong steel prop is versatile enough for a wide range of construction scenarios:

● Vertical support for slab formworks (any shape or size)

● Falsework support for bridges, highways, and industrial facilities

● Temporary structural bracing during renovations or expansions

● Raking shores for stability in uneven terrain

● Residential, commercial, and infrastructure projects

Why Choose Lianggong as Your Steel Prop Supplier?

With over 10 years of experience as a leading formwork and scaffolding manufacturer, Lianggong delivers more than just products—we provide peace of mind. Our steel props meet international standards (EN1065) and are backed by a strict quality management system. We offer one-stop service, including off-the-shelf and customized solutions, comprehensive after-sales support.

Trusted by customers worldwide for reliable quality and competitive prices, Lianggong steel prop is the smart choice for projects where safety, efficiency, and durability matter.

Ready to elevate your construction with a vertical support solution you can rely on? Click to explore detailed technical drawings, case studies, and customized quotes. Let’s build safer, faster, and more cost-effectively—together.

How to Contact Us?

Company: Yancheng Lianggong Formwork Co., Ltd.

Website: https://www.lianggongformwork.com https://www.fwklianggong.com https://lianggongform.com

Email: sales01@lianggongform.com

Tel: +86-18201051212

Address: No.8 Shanghai Road, Jianhu Economic Development Zone, Yancheng City, Jiangsu Province, China

Post time: Dec-01-2025