Are you struggling with inefficient concrete formwork that slows down your projects, compromises surface quality, or raises safety concerns? Look no further! Our Cantilever Climbing Formwork (CB-180&CB-240) is engineered to redefine your construction experience— combining speed, precision, durability, and safety to deliver exceptional results for large-area concrete pouring projects.

Whether you’re working on dams, piers, retaining walls, tunnels, basements, or underground workshops, our cantilever formwork system adapts seamlessly to your needs, eliminating redundant reinforcement work and cutting down construction cycles. It’s not just a tool—it’s a strategic investment to boost your project’s profitability and reputation!

Why Choose Our Cantilever Formwork System?

We don’t just offer formwork—we offer a comprehensive construction solution tailored to modern engineering demands. Here’s what makes us stand out from the crowd:

● Unmatched Load-Bearing Safety: The entire weight of brackets, formwork, and construction loads is fully borne by embedded anchors and wall-through tie rods. No additional scaffolding is needed, ensuring safe and stable high-altitude operations while keeping your job site clutter-free.

● Superior Concrete Quality: Equipped with imported double-sided coated high-quality plywood panels, our cantilever formwork delivers ultra-smooth and flat concrete surfaces. Say goodbye to tedious post-processing and hello to a flawless finish that impresses clients.

● Maximized Construction Efficiency: With a maximum one-time concreting height of 6 meters and a 600mm horizontal retraction function, our cantilever formwork system simplifies rebar binding, formwork cleaning, and release agent application. The CB-240 even allows formwork and climbing scaffolds to be moved as a single unit by crane, saving valuable time.

● Exceptional Versatility: Available in two models (CB-180 & CB-240) with main platform widths of 180cm and 240cm respectively. The CB-240 offers diagonal brace and truss types—truss type is ideal for heavy loads, high formwork erection, and narrow inclination ranges. Both models handle circular structures and inclined walls effortlessly.

● Cost-Effective Durability: All components are standardized, serialized, and localized, ensuring mature technology and reliable performance. The reusable anchor system (including climbing cones and tensile bolts) reduces material waste, while the wear-resistant panels extend service life—lowering your long-term operational costs.

What are key components of our cantilever formwork system?

Every part of our Climbing Formwork is designed to work in perfect harmony, guaranteeing stability, precision, and ease of use:

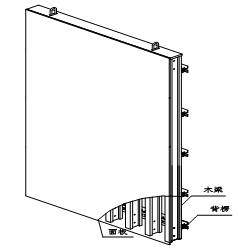

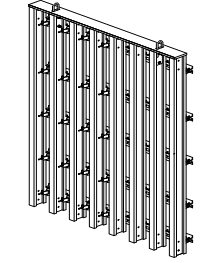

1. Formwork System

The heart of our solution, the formwork system features high-quality plywood panels supported by walers and timber beams. Standard units can be assembled into custom shapes to fit unique project requirements. Key advantages include:

● Imported double-sided coated plywood ensures smooth concrete surfaces and easy cleaning.

● Timber beams (H20 standard) serve as vertical ribs, connected to steel walers via flange clamps for stable support.

● Equipped with a retraction device for quick, labor-saving formwork stripping—Before pouring concrete, the formwork was coated with release agent to facilitate demolding., boosting efficiency.

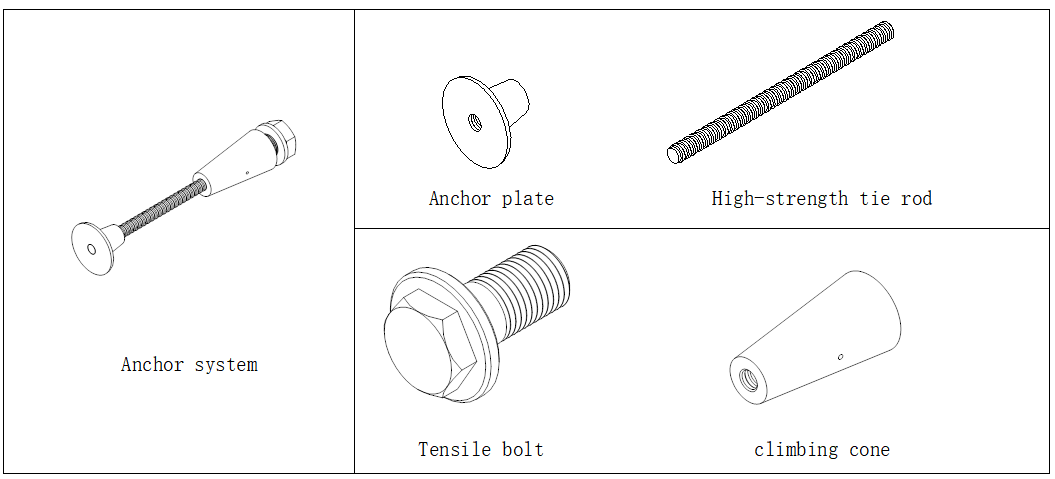

2. Anchor System

The backbone of safety and load-bearing, our anchor system consists of anchor plates (D20), tensile bolts (M30/M36), washer, High-strength tie rod (D20/L=300) and climbing cones (M30/20 or M36/20). It’s engineered to transfer high tensile and shear forces into fresh concrete, ensuring stable load support without wall-through tie rods (for CB-180). Highlights include:

● Precision-designed climbing cones with grease-applied surfaces for easy disassembly and repeated use.

● Tensile bolts ensure secure connection between brackets and concrete structures, withstanding lateral pressure up to 40KN/m².

● Simple installation and removal process—workers can operate safely on suspended platforms, reducing labor intensity.

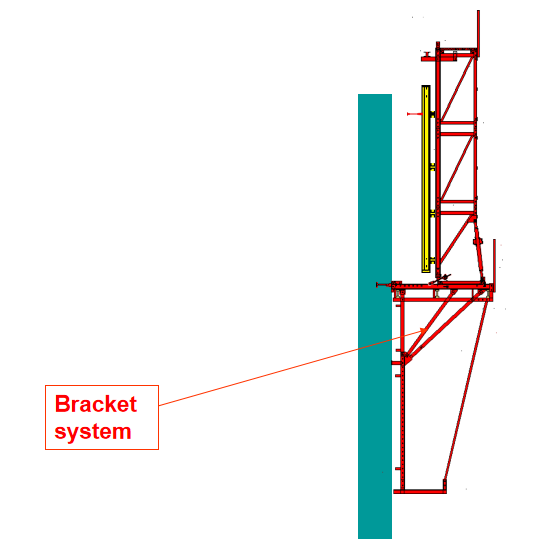

3.Bracket System

The support system that enables seamless climbing and stable operation, including load-bearing bracket, retrusive set, main waler, and suspended platforms. Available in diagonal brace and truss types (CB-240) to adapt to different load requirements:

● High load-bearing capacity: CB-240’s robust brackets allow large-scale scaffold units, reducing the number of anchor points and climbing times.

● Integrated suspended platforms: Provide safe workspaces for anchor removal and concrete surface treatment, eliminating the need for temporary scaffolding.

● Adjustable design: Vertical, lateral, and (for diagonal brace type) forward/backward tilt adjustments ensure precise formwork positioning, preventing grout leakage and joint misalignment.

What are the specifications of Cantilever Climbing Formwork?

We offer two high-performance models to match diverse project needs: CB-180 and CB-240, both are built with high-grade materials and undergo rigorous testing to ensure durability.

| ltem | CB-180 | CB-240 |

| Main bracket | Moderate load capacity optimization | Heavy-load & high-rise structural engineering |

| Platform Width | 180 cm | 240 cm |

| Adjustability | Vertical+ Horizontal adjustment | Vertical+ Horizontal + Diagonal brace tilt adjustment |

| Lifting unit type | Diagonal brace type and truss type | Diagonal brace type and truss type |

| Range of application | Standard bridge pierRetaining wall | Heavy-duty damLarge-scale tunnel |

| Max pouring height | 4.5m (Diagonal brace type)6m (Truss type) | 4.5m (Diagonal brace type)6m (Truss type) |

| Retractable stroke | 600 mm | 600 mm |

What are characteristics of CB-180?

● Economical and safe anchoring

The M30/D20 climbing cones have been designed especially for single-sided concreting using CB180 in dam construction, and to allow the transfer of high tensile and shear forces into the still fresh, unreinforced concrete. Without wall-through tie-rods, finished concrete is perfect.

● Stable and cost-effective for high loads

Generous bracket spacings allow large-area formwork units with optimal utilization of the bearing capacity. This leads to extremely economical solutions.

● Simple and flexible planning

With CB180 single-sided climbing formwork, circular structures can also be concreted without undergoing any large planning process. Even use on inclined walls is feasible without any special measures because additional concrete loads or lifting forces can be safely transferred into the structure.

What are characteristics of CB-240?

● High bearing capacity

The high loading capacity of the brackets allow very large scaffold units. This saves the number anchor points required as well as reducing climbing times.

● Simple moving procedure by crane

Through the strong connection of formwork together with the climbing scaffold, both can be moved as a single climbing unit by crane. Thus valuable time-savings can be achieved.

● Fast striking process without a cran

With the retrusive set, large formwork elements can also be retracted quickly and a minimum of effort.

● Safe with work platform

The platforms have assembled firmly with bracket and will be climbing together, without scaffolding but can work safely in spite of your high location.

Ready to Join Thousands of Satisfied Clients Worldwide?

From large-scale dam projects to complex pier constructions, our Cantilever Formwork has proven its reliability and efficiency in diverse engineering scenarios. Clients trust us for our consistent quality, professional support, and solutions that deliver on time and within budget.

Ready to take your construction projects to the next level? Click here to learn more about CB-180/CB-240 models, request a customized quote, or schedule a product demo. Let’s build excellence together!

Contact Information

Company: Yancheng Lianggong Formwork Co., Ltd.

Website: https://www.lianggongformwork.com https://www.fwklianggong.com https://lianggongform.com

Email: sales01@lianggongform.com

Tel: +86-18201051212

Address: No.8 Shanghai Road, Jianhu Economic Development Zone, Yancheng City, Jiangsu Province, China

Post time: Nov-24-2025