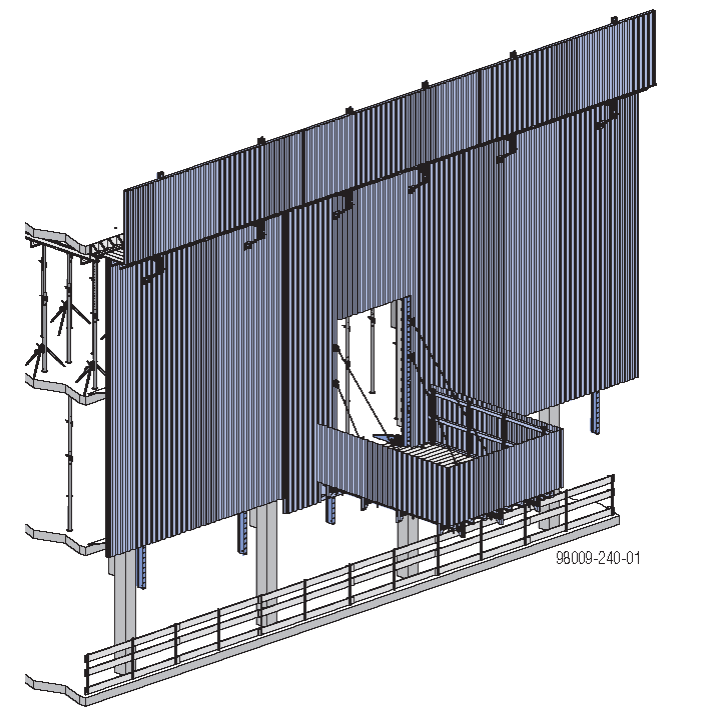

Are you seeking a cutting-edge safety solution that transforms high-rise construction with uncompromised protection, seamless operations, and boosted productivity? Our automatic climbing Protection Screen and Unloading Platform is engineered to redefine safety standards for high-rise tower projects—eliminating fall hazards, streamlining material transfer, and aligning with modern civilized construction requirements. Trusted by contractors worldwide, this self-climbing system delivers exceptional performance for frameworks, shear wall structures, and complex high-rise developments.

What Are Core Advantages that Set Our Protection System Apart?

● Self-Climbing Hydraulic Power: Equipped with an independent hydraulic lifting system, the protection screen climbs autonomously without relying on cranes. The one-to-four hydraulic configuration (one main unit + four cylinders) enables efficient lifting of up to four guide rail units at once, saving valuable construction time.

● 360° Comprehensive Safety Protection: Encloses up to 4.5 floors (or 2.5 floors) of the pouring area with high-strength color steel plates, forming an impenetrable barrier against falling objects and high-altitude accidents. Built-in anti-fall devices (load-bearing pins) and wind-resistant support ensure stability even in harsh conditions.

● Integrated Material Transfer Efficiency: The dedicated unloading platform (2-ton load capacity for standard models, 60KN for XCPS 60) allows seamless movement of formwork, scaffolding, and construction materials to upper floors—no disassembly required. After slab pouring, materials are directly lifted by tower cranes from the platform, slashing manpower and material costs.

● Versatile & Durable Design: Suitable for floor heights ranging from 2.7m to 4.5m, with standardized components for easy adaptation to different project needs. The exterior color steel plates double as advertising space, enhancing brand visibility for contractors.

● Compliant with Global Safety Standards: Meets strict on-site safety and civilization requirements, with anchor points designed to bear vertical loads of 30KN and horizontal loads of 60KN. The system’s structural design ensures stability, even when subjected to wind loads and dynamic construction forces.

What Are Parameters of Our Self-climbing Protection Screen?

| Working Pressure of Hydraulic System | 50 KN |

| Number of Platform | 0-5 |

| Width of Operating Platform | 900mm |

| Loading of the operating Platform | 1-3KN/㎡ |

| Loading of Unloading Platform | 2 Tons |

| Protection Height | 2.5 floors or 4.5 floors . |

What Are Key Components of Our Auto-climbing Protection Screen?

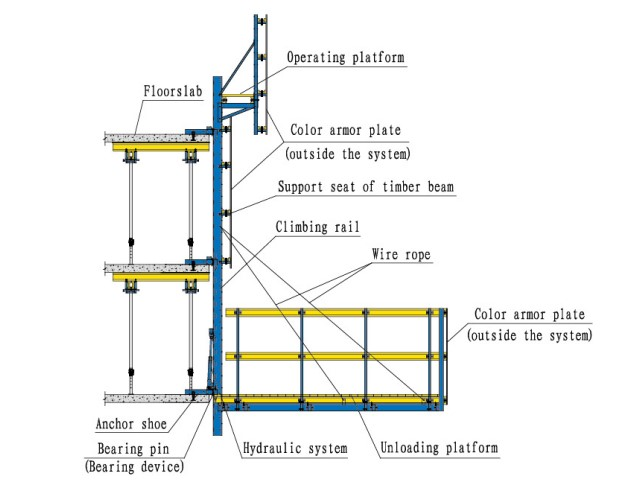

Here is the structure diagram of our automatic climbing protection screen and loading platform:

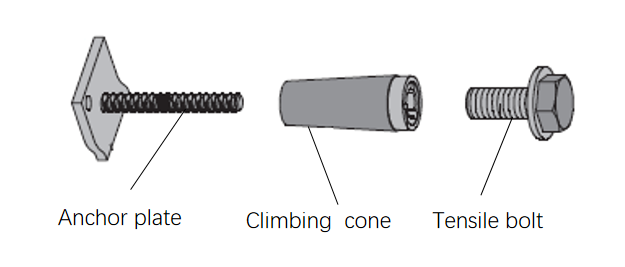

1. Anchor System

The backbone of structural safety, the anchor system consists of tensile bolt (M36/L=110), v-climbing cone (M36/D20) and anchor plate (D20). It bears the entire load of the system—including operators, materials, and the screen itself—with three versatile anchoring methods: through-floor, embedded cone, and through-wall.

2. Hydraulic System

Powering the self-climbing function, the hydraulic system features a mobile, reusable handcart-mounted hydraulic station. The system operates at a working pressure of 50KN, ensuring efficient climbing without crane assistance. Its compact design allows easy movement across the construction site, supporting sequential climbing of multiple screen units.

3. Operating Platform

Designed for on-site operations such as reinforcement assembly, concrete pouring, and material storage, the operating platform offers a safe and stable workspace. With a standard width of 900mm and a load capacity of 1-3KN/㎡, it accommodates workers and tools comfortably.

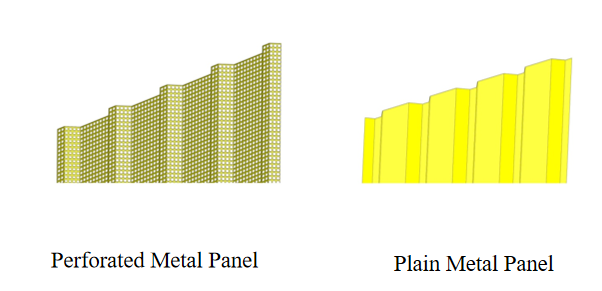

4. Protection System

The protection system forms a full enclosure around the construction area using 0.5-0.8mm thick color steel plates (perforated or plain) and 80×80×2mm square steel tube keels. Perforated plates ensure 50% light transmission, maintaining good visibility inside the construction zone. The system covers up to 4.5 floors, with upper railings extending 2.5m above the top working surface for maximum fall protection. Unit gaps (10-35cm) are sealed with custom joint plates, eliminating potential hazards.

5. Unloading Platform

A game-changer for material transfer, the unloading platform is a modular steel structure with a 2-ton (standard) or 60KN (XCPS 60) load capacity. It features a factory-welded chassis (2[12 main beams, [10 secondary beams, and 3mm chequered steel plates), a saddle-shaped front stop for easy material stacking, and side enclosures for safety. Equipped with Φ20 attachment steel cables and Φ10 wind-resistant cables, it stays stable during lifting and material handling. The platform climbs with the protection screen, positioned one floor above the screen’s base for convenient material transfer even when the screen is not fully elevated.

6. Climbing Rail

The climbing rail is the guide for the self-climbing system, available in lengths ranging from 12.5m to 18.5m to match floor heights (2.7m-4.5m). It works with the lifting mechanism and hangers to ensure vertical and stable climbing. Rail spacing (3.5m-5.0m) is optimized based on floor height and wind load, while the rail’s high-strength steel construction supports the entire system’s weight. The rail interacts with the anchor system’s load-bearing pins, enabling automatic locking at each climbing stage.

Why Choose Our Protection Device for Construction?

We combine innovative engineering with user-centric design to deliver a solution that enhances safety, reduces costs, and accelerates project timelines. Our system eliminates the need for external scaffolding, simplifies material transfer, and ensures compliance with global construction safety norms. Whether you’re building a 20-story residential tower or a 50-story commercial complex, our product adapts to your needs with reliable performance and long-lasting durability.

Ready to transform your high-rise construction site? Click to explore detailed case studies, technical drawings, and customized quotes. Let’s build safer, faster, and smarter—together.

How to Contact Us?

Company: Yancheng Lianggong Formwork Co., Ltd.

Website: https://www.lianggongformwork.com https://www.fwklianggong.com https://lianggongform.com

Email: sales01@lianggongform.com

Tel: +86-18201051212

Address: No.8 Shanghai Road, Jianhu Economic Development Zone, Yancheng City, Jiangsu Province, China

Post time: Nov-25-2025