When it comes to building high-rises, bridge towers, nuclear power plants, or large-scale industrial structures, efficiency, safety, and precision are non-negotiable. Our Hydraulic Auto-Climbing System (ACS) redefines construction standards by eliminating reliance on external lifting equipment, enabling self-powered, synchronized climbing that cuts project timelines and reduces labor costs.

Why ACS Stands Out: Core Advantages

Our Climbing Formwork System is designed to solve the biggest pain points of high-altitude construction, offering unmatched value:

Self-Sufficient Climbing: Powered by an integrated hydraulic jacking system, self climbing formwork system enables the formwork frame and guide rail to “climb” each other—no cranes, no extra hoists, just smooth, independent operation.

Uncompromised Safety: It adheres to strict global safety standards, with zero risk of tilting or instability during climbing.

Rapid Project Delivery: Climbs at ~300mm/min, accelerating progress to 5 days per floor (average). The frame assembles once and climbs to the top, avoiding repeated disassembly/reinstallation.

Precision & Quality: Minimizes structural errors with layer-by-layer deviation correction, delivering fair-faced concrete surfaces that require no post-finishing.

Space & Cost Savings: Compact design reduces on-site clutter; reusable components (anchor parts, guide rails) lower material waste and long-term costs.

Product series: LG-100 & LG-120

We offer two high-performance models to match diverse project needs—from high-rise buildings to super-tall structures. Both are built with high-grade materials and undergo rigorous testing to ensure durability.

| Specification | LG-100 | LG-120 |

| Rated Thrust | 100 KN | 120 KN |

| Hydraulic Pressure | 25 Mpa | 25 Mpa |

| Cylinder Stroke | 300 mm | 400 mm |

| Max Frame Span | ≤4.5 m (between embedded points) | Customizable (up to 6 m) |

| Platform Load Capacity | 0.75–3.0 KN/m² | 1.0–4.0 KN/m² |

| Structural Type | Separate Truss/ Composite Truss / Diagonal Brace | Separate Truss/ Composite Truss / Diagonal Brace |

| Key Applications | High-rises, shear walls, bridge piers | Super high-rises, nuclear plants, bridge towers |

LG-100 LG-120

Key Components & Systems: Built for Reliability

Climbing Formwork integrates four high-performance subsystems, each engineered to work in perfect harmony—ensuring stable operation, easy maintenance, and long service life.

1. Formwork System: Lightweight, Strong, & Versatile

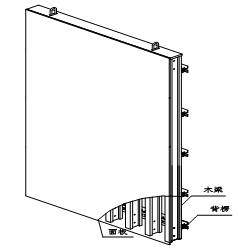

The formwork system is the “face” of Self climbing Formwork, designed for high-altitude efficiency and superior concrete finish:

- Core Material: Lightweight yet durable timber beam plywood (15mm/18mm thickness), ideal for reducing frame weight without compromising strength.

- Design Features: Modular assembly allows customization for straight walls, columns, or curved surfaces. Timber beams (H20 standard) serve as vertical ribs, connected to steel walers via flange clamps for stable support.

- Performance: Panels offer excellent water absorption and air permeability, preventing concrete surface defects. They support up to 35 turnovers, maximizing cost efficiency.

2. Anchor System: The “Backbone” of Safe Climbing

The anchor system secures auto climbing formwork system to the structure, withstanding vertical loads, horizontal pressure, and bending forces. It includes reusable components for sustainability:

- Components: Anchor plates (D26.5/D20), high-strength tie rod (D26.5/D20), Tensile bolts (M42/M36), and climbing cones ( M42/26.5 or M36/20).

- Key Advantages: Two embedded assembly options (Type A for heavy loads, Type B for standard loads) adapt to project requirements. Climbing cones are coated with release agent for easy removal and reuse.

- Safety: Load-bearing bolts undergo quenching and flaw detection (RC25-30 hardness) to ensure they can handle extreme construction pressures.

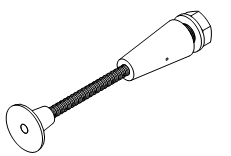

3. Hydraulic System: Powering Smooth, Synchronized Climbing

The hydraulic system is the “engine” of automatic climbing formwork, delivering consistent power for seamless climbing:

- Core Parts: Hydraulic pump station (1.5KW motor, AC380V), double-acting cylinders, upper/lower commutators, and high-pressure hoses (M14×1.5 connections).

- Performance: Pump station flow rate of 2L/min (per unit) enables a climbing speed of ~300mm/min. Commutators control the direction of force (lift frame or guide rail), enabling mutual climbing.

- Safety: Pressure is limited to ≤16MPa during operation; a dedicated console with pressure gauges ensures real-time monitoring and error correction.

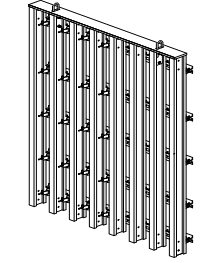

4. Bracket System: Stable Support & Full-Range Operation

The bracket system provides structural stability and multi-layer work platforms, eliminating the need for temporary scaffolding:

- Core Components: Load-bearing tripods (with 140mm-diameter diagonal braces), retrusive set (600–700mm adjustment range), climbing rails (H150×150 Q235 steel), wall-attached device, main walers and operating platforms (top, main, medium, suspended).

- Key Features: Loading-bearing bracket is connected via H15 steel to form a unified frame; retrusive set allows formwork to retract for steel reinforcement binding and cleaning.

- Platforms: Each platform is non-slip, load-tested, and equipped with guardrails—ensuring worker safety while providing space for concrete pouring, formwork maintenance, and material storage.

Simple Climbing Workflow: Save Time & Labor

Climbing formwork follows a streamlined, repeatable process that minimizes on-site complexity. A single team can complete climbing in hours, not days:

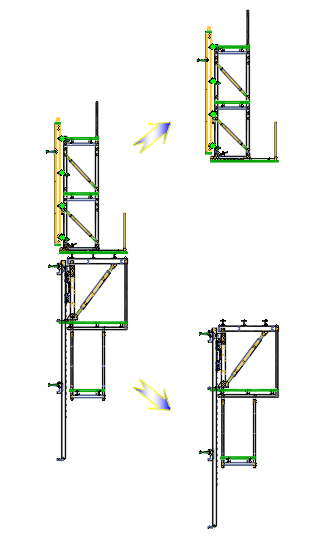

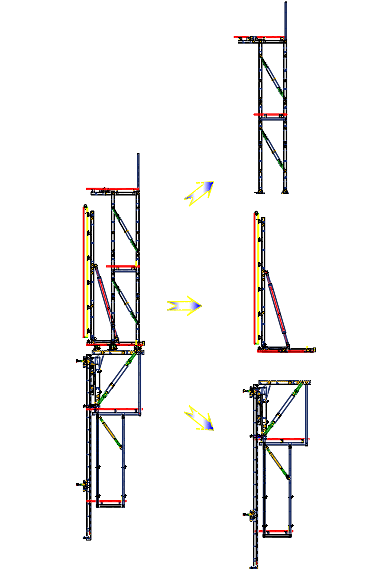

- Post-Concrete Preparation: After concrete pouring, strip the formwork and retract it using the rearward movement device.

- Anchor Installation: Mount load-bearing bolts, embedded supports, and climbing cones in the reserved holes (left by the previous climb).

- Climbing Rail Lifting: Adjust commutators to lift the guide rail to the new anchor position; lock it in place with safety pins.

- Frame Climbing: Reset commutators to lift the entire frame along the guide rail; verify synchronization and lock the frame.

- Reinforcement & Formwork Setup: Tie rebar, clean the formwork, apply release agent, and reposition the formwork for the next concrete pour.

Quality & Safety: Beyond Industry Standards

We prioritize safety and durability in every component, ensuring climbing formwork system meets or exceeds global construction regulations:

- Material Testing: All steel parts (guide rails, tripods, bolts) are made of Q235 or 10.9-grade alloy, with corrosion resistance and impact resistance testing.

- Safety Protocols: Climbing is only permitted when concrete strength reaches ≥10MPa; prohibited in 8+ grade winds, thunderstorms, or low visibility.

Partner With Yancheng Lianggong: Your Trusted ACS Supplier

Choosing self climbing formwork means partnering with a company that delivers more than just products—we offer end-to-end support for global projects:

Custom Solutions: Tailor auto climbing formwork system to your project’s unique needs (height, load, structure) with our in-house engineering team.

Global Delivery: Fast shipping to 50+ countries, with dedicated logistics support to avoid delays.

After-Sales Service: Technical support, on-site maintenance, and component replacement to keep your project on track.

Ready to elevate your high-rise construction with climbing formwork system? Contact us today for a free technical proposal, customized quote, or virtual product demo!

Contact Information

Company: Yancheng Lianggong Formwork Co., Ltd.

Website: https://www.lianggongformwork.com https://www.fwklianggong.com https://lianggongform.com

Email: sales01@lianggongform.com

Tel: +86-18201051212

Address: No.8 Shanghai Road, Jianhu Economic Development Zone, Yancheng City, Jiangsu Province, China

Post time: Nov-21-2025