• Material

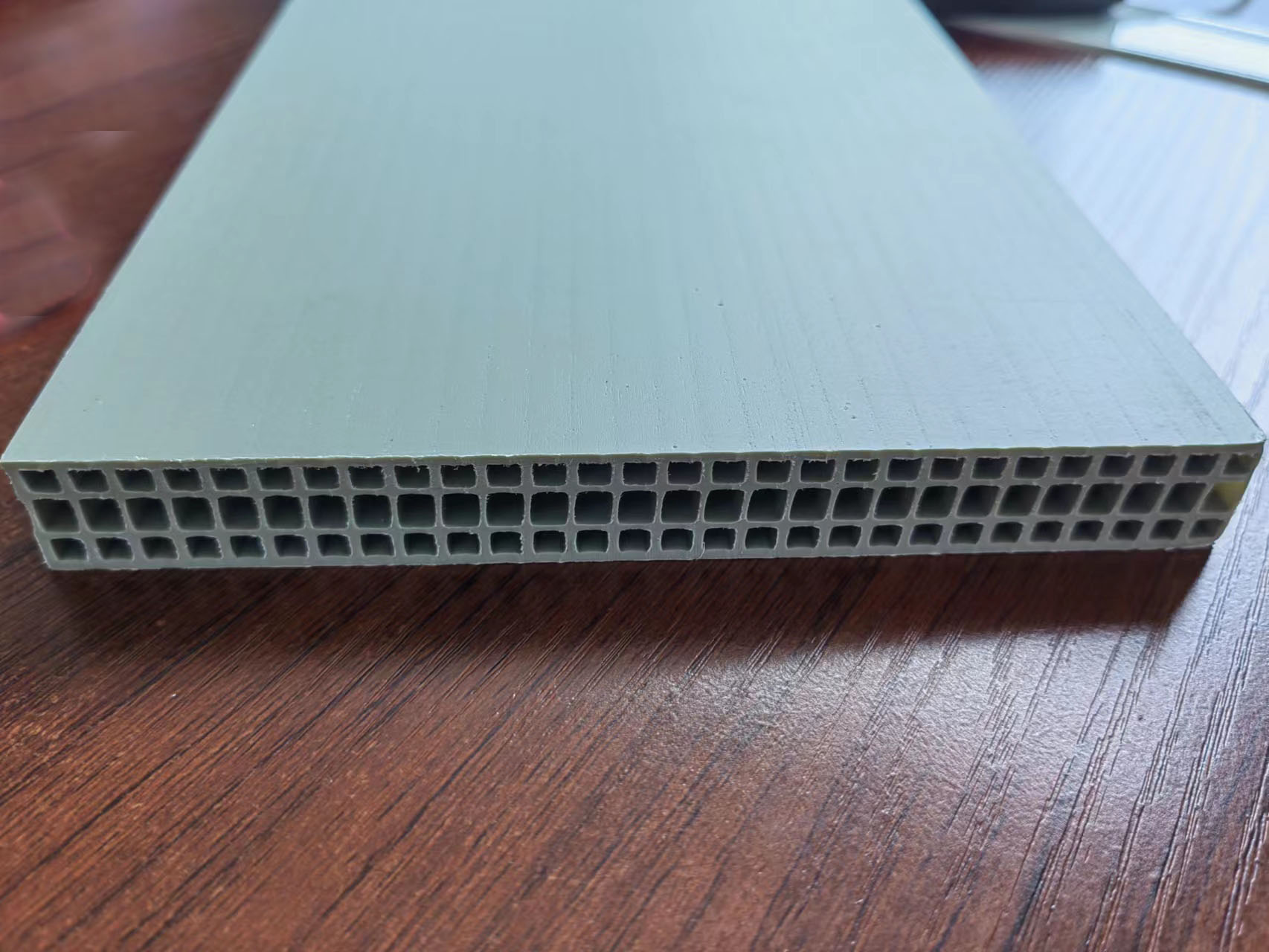

The material of hollow plastic formwork is Polypropylene,the melting point can be as high as 167C.PP Vicat softening temperature of 150 'C. Heat- resistant,corrosion-resistant products available,have a stronger impact strength.Impact strength increases with the increase of ethylene. The surface stiffness and scratch resistance are very good.

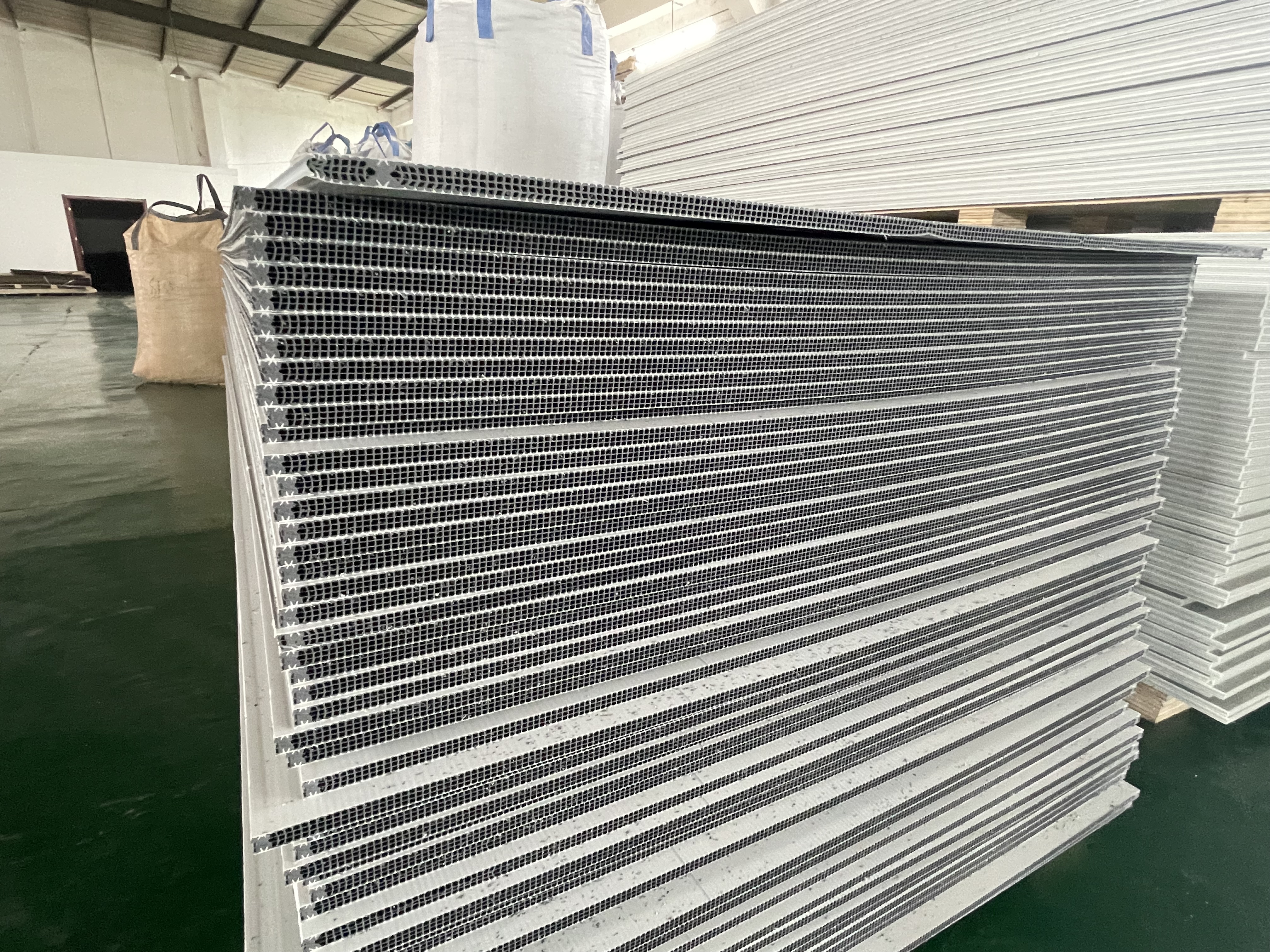

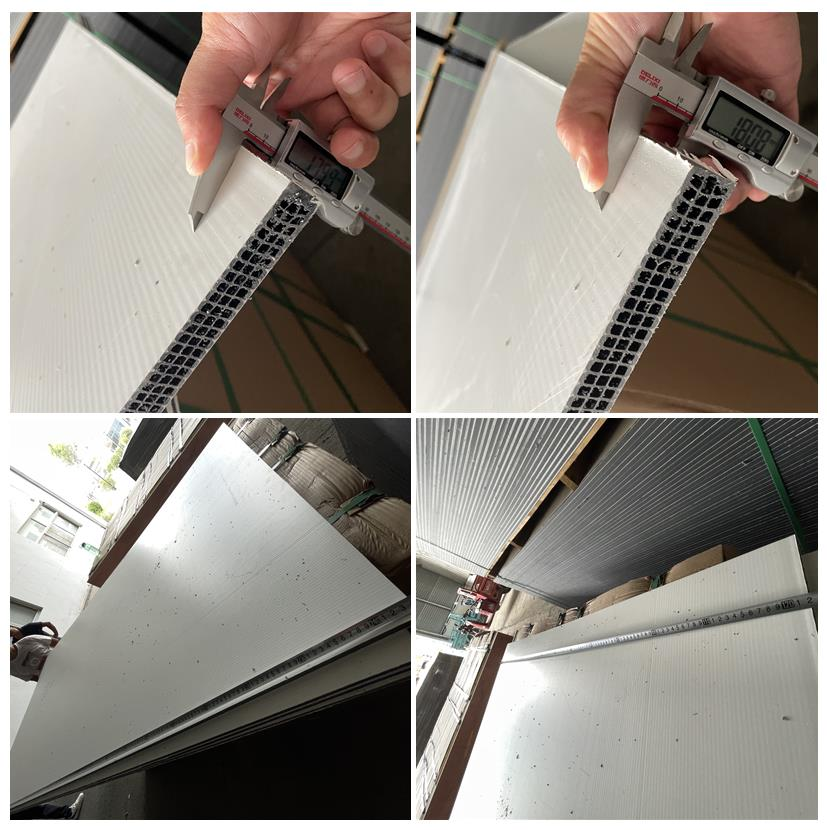

• Common size and packing detail

|

No |

Specification |

Weight |

Quantity(pcs) |

|

|

20GP |

40HQ |

|||

|

1 |

1830*915*12 |

12 |

1000 |

2200 |

|

2 |

1830*915*14/15 |

14 |

1000 |

1900 |

|

3 |

1220*2440*12 |

18 |

600 |

1350 |

|

4 |

1220*2440*15 |

25 |

480 |

1080 |

|

5 |

1220*2440*18 |

29 |

400 |

900 |

|

Can also be customized according to your needs.Available thickness:12-20mm Max length 3000mm,Max width 1250mm. |

||||

• Advantage

1.Waterproof

Hollow plastic formwork is weather-resistant, rain and shine are no longer an issue.

2. Lightweight

It is lighter, easier to carry and release worker from heavy labor.Manual operation, no crane required REDUCE 20% labor cost than plywood.

3.Surface does not require maintenance

High pressure water jet flushes the surface of the plastic template, but the metal formwork requires surface maintenance.

4. High workability

User-friendly, work well with saw, nail, drill, cut, etc.Compatible with other materials such as wood, steel, aluminum, etc.

5.Reusable

After testing, the normal use of this formwork can be repeated more than 50 times, which can greatly reduce the construction cost, and the used formwork can be recovered after use.

6. Realize fair-faced concrete

The surface is smooth and clean, with good peelability with concrete, easy to demould, which can greatly speed up the construction progress and help to realize fair-faced concrete.

• Delivery

It has best seller in Russia,Mauritius ,Macedonia, Turkey,Maldives,Egypt,Mexico,Pakistan,Saudi Arabia.

Post time: Aug-12-2022