H20 Timber Beams are an important component of the wooden formwork system and have a wide range of applications in building formwork. The wooden beam flange is made of imported Nordic spruce, ensuring the high quality of the wooden beam. The company has a large woodworking workshop and a first-class woodworking beam production line. The daily production capacity of woodworking beams exceeds 4000 meters.

H20 Timber Beam is a lightweight structural component made of solid wood sawn timber as the flange, multi-layer board or solid wood sawn timber as the web, bonded into an I-shaped section with weather resistant adhesive, and coated with anti-corrosion and waterproof paint on the surface. In cast-in-place reinforced concrete structure formwork engineering, it can form a horizontal support formwork system when used in conjunction with multi-layer slabs and vertical supports; It can form a vertical formwork system when used together with multi-layer plates, slant support, split bolts, etc. The most prominent features of wooden beams are high stiffness, light weight, strong bearing capacity, low cost, and high reuse rate.

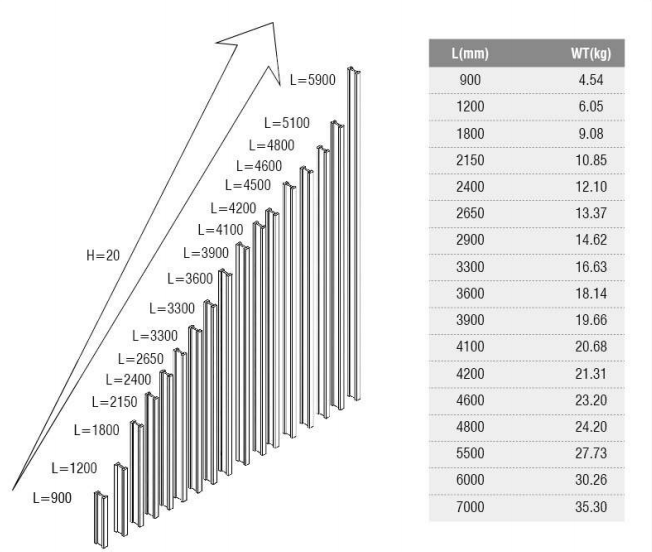

Next,we will introduce the standard specifications for H20 Timber Beam, the allowable bending moment is 5KN▪M,the allowable shear force is 11KN,with a length range of 900-7000mm and a weight range of 4.54-35.30kg. Standard holes can be drilled at both ends of the wooden beam as needed. During the construction process, wooden beams can be extended as needed. The company can also customize wooden beams of any length according to customer needs.

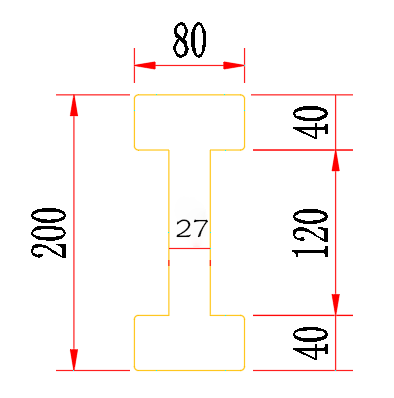

The standard height of H20 Timber Beam is 200mm and the width is 80mm; the flange thickness is 40mm and the web thickness is 35mm. The commonly used lengths are 1.2m, 2.4m, 3.0m, 3.6m, and 4.8m, and wooden beams with different lengths or web thicknesses can also be produced according to different needs.

The panel is made of laminated multi-layer boards, such as WISA board or high-quality domestic multi-layer boards, which can be used as panel materials. Visa board is a laminated multi-layer plywood produced by Finnish company Shoman. Its main characteristics include high strength, good elasticity and toughness, high processing size accuracy, strong surface coating strength, strong wear resistance, good durability, and uniform and stable physical and chemical properties. Its normal usage cycle can reach 40 to 60 times, which helps improve construction efficiency and save construction costs. High quality domestic multi-layer boards are usually used in engineering projects with low turnover times, with less than 10 turnover times.

Post time: Aug-16-2025